Advantages of Organic Solar Cell | disadvantages of Organic Solar Cell

This page covers advantages and disadvantages of Organic Solar Cell. It mentions Organic Solar Cell advantages or benefits and Organic Solar Cell disadvantages or drawbacks.

Introduction: Solar cell is a device which converts solar energy into electric energy. It generates electricity from radiant energy from sunlight using photovoltaic effect. In order to generate desired solar power, number of solar cells are connected together. This configuration of solar cells is known as PV modules or solar panels.

Following are the three types of solar cells. Silicon Solar Cell (First generation) Thin Film Solar Cell (Second generation) Organic Solar Cell (Third generation)

What is Organic Solar Cell?

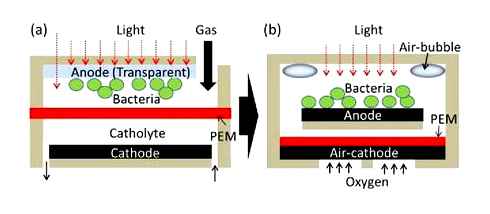

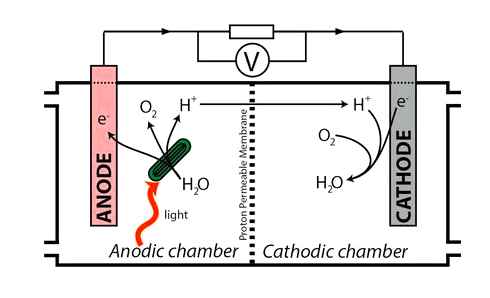

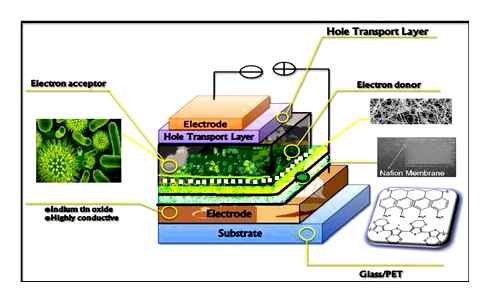

Introduction: It consists of thin layers of organic semiconducting materials. Hence the name Organic Solar Cell. The basic structure as shown in figure-1(a) consists of photoactive layer sandwiched between two thin film electrodes where one electrode is semi-transparent. The semi-transparent electrode allows sunlight to enter into the device. Photoactive layer is composed of two different types of semiconductors (e.g. donor, acceptor) which forms hetero-junction similar to p-n junction of inorganic solar cell. Sunlight consists of radiant particles known as photons.

➨Working principle of Organic solar cell as shown in figure-1(b) can be summarized as follows. The photons from sunlight is absorbed into photoactive donor material. Above process generates excitons i.e. tightly bound electron-hole pair. The excitons move towards Donor-Acceptor interface where it get separated into charge carriers (i.e. electrons and holes) at the interface. After separation process, holes move toward donor material (i.e. anode) and electrons move toward acceptor material (i.e. cathode). Collection of charges at relative electrodes results into generation of electricity due to stready flow of charges into external circuit.

Benefits or advantages of Organic Solar Cell

Following are the benefits or advantages of Organic Solar Cell: ➨It is light in weight. ➨It is semi-transparent. ➨It is environmental friendly. ➨Organic Solar cells are 1000 times thinner compare to silicon solar cells. Hence it results into huge savings on materials and consecutively they are cheaper. ➨It is flexible due to use of PV modules. ➨It offers short energy payback time. ➨It is easy to integrate.

Drawbacks or disadvantages of Organic Solar Cell

Following are the drawbacks or disadvantages of Organic Solar Cell: ➨The efficiency of organic solar cells is less (about 5%) compare to silicon solar cells (about 15%). They are stable in the dark but degrade in the light conditions. over as electricity can not flow very easily in organic solar cells (OSCs), its efficiency is limited. This is due to poor generation as well as extraction of electrical charges in OSC. ➨Its lifetime is less compare to inorganic solar cell as organic materials degrade rapidly in ambient exposure. Moisture and air along with sunlight further degrades its performance over time.

Bio solar cells

Home / Energy Power / Renewables / Organic Solar Cell Market

Organic Solar Cells Market Size, Share and COVID-19 Impact Analysis, By Application (Building Integrated Photovoltaic. Portable Electronics, Defense Application, Conventional Solar, and Others), and Regional Forecast, 2020-2027

Report Format: PDF | Latest Update: Aug, 2021 | Published Date: Jan, 2021 | Report ID: FBI101555 | Status : Published

The global organic solar cells market size was USD 55.63 million in 2019. The global impact of COVID-19 has been unprecedented and staggering, with clear aligners witnessing a negative demand shock across all regions amid the pandemic. Based on our analysis, the global organic solar cells market will exhibit a huge decline of.19.2% in 2020. The market is projected to grow from USD 44.9 million in 2020 to USD 101.29 million in 2027 at a CAGR of 12.30% in the 2020-2027 period. The sudden rise in CAGR is attributable to this market’s demand and growth, returning to pre-pandemic levels once the pandemic is over.

Organic solar cells are a third-generation photovoltaic technology using organic materials to harvest energy from light, outdoor, as well as indoor. An organic cell, also called a plastic solar cell, utilizes organic electrons. These are a branch of electronics that deals with conductive organic polymers, or small organic modules, for light absorption and charge transport. This is done so that electricity can be produced from sunlight via the photovoltaic effect. The increasing dependency on renewable energy sources for power generation and subsidies tax benefits by respective governments for power generation will positively influence market growth.

Disruption in Supply Chain Due to COVID-19 Pandemic to Affect Solar Projects Severely

The COVID-19 pandemic has created economic turmoil across industries and businesses worldwide. The lockdowns social distancing restrictions in the wake of the pandemic have crippled economic activities, thereby disrupting supply chains, delaying projects, creating a shortage of labor, and causing demand for goods and services to tumble. Governments across the globe are taking multiple efforts to lessen the suffering caused by this pandemic. The global renewable sector is generally dependent on imports from other regions.

As per the Government of India, around 80% of solar cells and modules in India imports from China along with other equipment such as inverters. Several solar projects in India and worldwide are getting delayed due to the initial slowdown of manufacturing activities in China, followed by lockdown restrictions in various countries across the globe. over, key solar equipment suppliers have also observed production delays due to COVID-19, resulting in a huge backlog for fulfilling orders.

LATEST TRENDS

Rising Demand for Electricity is a Prominent Trend

The speedy growth of population, flourishing industrial sector and high growth in infrastructure development are set to lead to a significant rise in the demand for electricity. As the demand is rising, countries are expanding their power generation capacities by increasing the capacity of the existing ones or installing new plants. Stringent government rules are enforcing companies to incline towards the use of renewable energy sources for power generation and particularly towards solar and wind energy. This is expected to push the organic solar cells market growth during the forecast period.

DRIVING FACTORS

Surging Demand for BIPV to Drive Growth of the Market

Building-integrated photovoltaics (BIPV) products offer added functionalities to a building, unlike traditional construction materials. The use of this technology converts buildings from energy consumers into energy producers. To achieve this, the construction technology is required to be merged with BIPV technology. BIPVs protect buildings from climatic conditions and noise. over, they offer thermal insulation. This technology decreases the total building material and mounting costs, as BIPVs do not require brackets and rails. Henceforth, their popularity has been growing constantly. Designers and architects use BIPV products with innovative methods, whereas manufacturers continue to develop new products to meet the rising demand.

Favorable Government Initiatives and Policies to Fuel Growth

To address various challenges associated with climate change, several regions are developing policies to move toward ultra-low-energy buildings. The European Union (EU) Energy Performance of Buildings Directive (EPBD) requires all new buildings to be nearly-zero-energy buildings (nZEB) in every EU member country by the end of 2020. The U.S., Japan, and South Korea have also formulated ZEB policies and set specific goals. For example, the State of California has set the ambitious goal that states “all new residential buildings in the state would be zero net energy (ZNE) by 2020 and all new commercial buildings would be ZNE by 2030.” Such supportive policies are expected to drive the growth of the global market.

RESTRAINING FACTORS

Higher Cost of BIPV Systems and Lack of Awareness to Hinder Growth

The use of building-integrated photovoltaic technology can convert buildings from energy consumers into energy producers. In order to achieve this, construction technology is required to be merged with BIPV technology. The organic photovoltaic (OPV) technology is new and expensive for curtain walls and other aspects of buildings. over, the lack of awareness and inadequate marketing of BIPV products in Vietnam, the Philippines, and certain other countries in Africa are likely to hamper the global market during the forecast period.

SEGMENTATION

By Application Analysis

Building-integrated Photovoltaic (BIPV) Segment to Grow at the Highest Rate during 2020-2027

Based on the application, the market is segmented into building-integrated photovoltaic (BIPV), portable electronics, defense applications, conventional solar, and others. The BIPV segment held a dominant organic solar cells market share in 2019. Encouraging government policies and guidelines regarding enhanced renewable installations are projected to strengthen the building-integrated photovoltaic (BIPV) installations over the forecast period. It offers an effective and sustainable solution for retrofitting structure exterior while providing an aesthetic appeal to the building. It also improves the building’s energy efficiency by delivering significant savings on conventional electricity consumption. Portable electronics is another major segment of the market and is expected to grow significantly during the forecast period owing to the high demand in Europe and North America.

REGIONAL INSIGHTS

Europe is anticipated to lead the global market for organic solar cells over the forecast period. Large investments in RD for organic solar cells technology by countries, including Germany, France, and the U.K., would contribute to the region’s large market share. The BIPV technology in Europe is in a transition period and is being positively impacted by the regulatory framework. The Directive on Energy Performance in Buildings (EPBD) and the Renewable Energy Directive were set up by the European Union (EU), paving the way for near-zero energy buildings.

Asia Pacific is anticipated to exhibit significant growth during the forecast period due to the increasing investments by major companies, particularly in China and Japan. China and India are set to be a potential market owing to government regulations that support power generation by renewable resources. The demand for BIPV products in Asia Pacific is increasing continuously as these products are adding unique visual elegance and architectural beauty to buildings. North America held the second-largest share of the market owing to the presence of small scale manufacturers in the region. However, Latin America and the Middle East and Africa held the least share of the market.

KEY INDUSTRY PLAYERS

Key Participants Focus on Product Innovation to Diversify Their Portfolios and Expand Sales Horizons

The global market is consolidated owing to the limited number of players operating in the market. Currently, Heliatek, ARMOR, infinityPV ApS, and Solarmer Energy, Inc. are leading the market. They accounted for a dominant share in 2019.

Major players in the market are employing several strategies to consolidate their positions in this market. One of the preferred strategies is the development of novel solutions that will help them to diversify their product portfolios and expand their sales horizons. Additionally, many academic institutes are conducting ground-breaking research, exploring the possible applications of OPVCs. For instance, in December 2019, the Fraunhofer Institute for Laser Technology-led EffiLayers project in the North Rhine-Westphalian region in Germany is researching the development of thin-film organic PVs that are flexible and printable. The research would enable manufacturers in the region to develop newer technologies in the market.

LIST OF KEY COMPANIES PROFILED:

- Heliatek (Germany)

- ARMOR (France)

- infinityPV ApS (Denmark)

- Solarmer Energy, Inc. (U.S.)

- NanoFlex Power Corporation (U.S.)

- Optodot (U.S.)

- Eni (Italy)

- New Energy Technologies Inc. (U.S.)

- Novaled GmbH (Germany)

- Brite Solar (Greece)

REPORT COVERAGE

The organic solar cells market research report includes a detailed solar power industry analysis and focuses on key aspects such as leading companies and leading applications of the product. Besides this, it offers insights into the market trends and highlights key industry developments. In addition to the aforementioned factors, the report encompasses several factors that have contributed to the growth of the advanced market over recent years.

REPORT SCOPE SEGMENTATION

Study Period

Organic solar cells: all you need to know

Organic solar cells are a type of solar cell that is made out of carbon-based materials. This means that the cells are made from carbon-based molecules as opposed to inorganic materials like silicon. While These cells have been around for a while, they have only recently started to be commercialized. In this article, we will take a closer look at what organic solar cells are, how they work, and some of their benefits and drawbacks.

What are organic solar cells?

Organic solar cells are made from carbon-based materials that are carbon-based. They are created using a process called vapor deposition. Here organic molecules are deposited onto a substrate to create a thin film. These molecules used to make these cells can be either small molecules or polymers. However, these cells currently have lower efficiency ratings than their silicon counterparts. Researchers are trying to make these carbon-based cells work better. This is because they can become a more practical way to make clean energy.

How do they work?

Organic solar cells are a type of solar cell that uses carbon-based materials to convert sunlight into electricity. They are made in the same way as monocrystalline and polycrystalline silicon solar cells. Each of them generates energy through the photovoltaic effect.

The photovoltaic effect is the atomic-level conversion of light into electricity, and it occurs in three steps. First, the solar cell absorbs light in the form of photons. Second, the photons knock electrons free from the semiconducting material. Third, the free electrons generate an electrical current through charge carriers. This current is then distributed throughout your house. They are more efficient than traditional solar cells because they can absorb a wider range of sunlight. These cells are also less expensive to produce than traditional solar cells. This makes them a more affordable option for those looking to switch to renewable energy sources.

The advantages

Organic solar cells have many advantages over traditional silicon-based solar cells. Some include their flexible and lightweight construction, their low production costs, and the abundance of ingredients needed to make them. over, they are more durable than conventional solar modules due to their flexible nature. Because of this, carbon-based solar cells are becoming more and more popular for both business and home use.

The disadvantages

One of the biggest drawbacks is power conversion efficiency. Organic solar cells typically achieve efficiency ratings of between 8% and 12%. In contrast, silicon cells can achieve efficiencies ranging from 20% to 25%. Another issue is lifespan. Carbon-based materials degrade significantly quicker when exposed to the environment. This means that these cells have a much shorter lifespan than regular solar cells. As research and development on these cells goes on, it is hoped that these problems will be solved.

The gears of an organic photovoltaic cell

An organic solar cell (OPV) is a solar cell that uses organic electronics for light absorption and charge transport to generate electricity from sunlight. OPVs are made from organic materials and have attracted attention because of their potential to be manufactured cheaply and flexibly. They can be made using solution-based processing techniques such as inkjet or screen printing. They are compatible with large-area, low-cost cytogenetic and molecular analysis (CMAO) manufacturing.

The organic semiconductor material used in the active layer of an OPV can be any organic compound that absorbs light in the visible spectrum. Common organic semiconductors include conjugated polymers and small molecules.

The choice of organic semiconductor material has a significant impact on the performance of the solar cell. Polymer-based OPVs typically have lower power conversion efficiencies than those made from small molecules. However, they are usually cheaper to produce. Small molecule OPVs often use fullerene derivatives as acceptor materials. Fullerenes are efficient electron acceptors, but they are relatively expensive. One way to lower the cost of small molecule OPVs is to use new acceptor materials that are cheaper than fullerenes but still accept electrons well.

Organic solar cells’ potential

Organic solar cells, also called organic photovoltaics (OPVs), are solar cells made from carbon-based materials. They are generally composed of small molecules or polymers that are held together with organic ligands. They are fabricated using low-cost solution processing techniques such as screen printing, inkjet printing, and doctor blading.

Due to their flexibility and light weight, organic solar cells hold the potential to be used in a variety of applications where traditional silicon-based solar cells cannot be used. However, these cells currently have lower efficiency levels than their inorganic counterparts and are not as widely used. Despite these challenges, research is ongoing to improve the efficiency of them and make them more commercially viable. With improvements in materials science and engineering, these cells are likely to play a big role in the future of clean energy.

Phenanthroline-carbolong interface suppress chemical interactions with active layer enabling long-time stable organic solar cells

To restrain the chemical reaction at cathode interface of organic solar cells, two cathode interfacial materials are synthesized by connecting phenanthroline with carbolong unit. Consequently, the D18:L8-BO based organic solar cell with double-phenanthroline-carbolong achieve the highest efficiency of 18.2%. Double-phenanthroline-carbolong with larger steric hindrance and stronger electron-withdrawing property confirms to suppress the interfacial reaction with norfullerene acceptor, resulting the most stable device. Double-phenanthroline-carbolong based device can sustain 80% of its initial efficiency for 2170 h in dark N2 atmosphere, 96 h under 85 o C and keep 68% initial efficiency after been illuminated for 2200 h, which are significantly better than bathocuproin based devices. over, superb interfacial stability of double-phenanthroline-carbolong cathode interface enables thermal posttreatment of organic sub-cell in perovskite/organic tandem solar cells and obtained a remarkable efficiency of 21.7% with excellent thermal stability, which indicates the potentially wide application of phenanthroline-carbolong materials for stable and efficient solar device fabrications.

Introduction

Organic solar cells (OSCs) attract increasing attention for merits like printable fabrication processing, lightweight, flexible and wearable nature 1,2. Due to broad absorption to red and infrared light and efficient electron transport, the nonfullerene acceptors (NFAs) based OSCs boosted efficiency from 6.8% in 2015 3 to currently, over 19% 4,5. However, the long-term stability under working conditions has always been a major obstacle for their further commercialization 6.

The sequential improvement of OSCs has benefitted from the innovation of highly efficient polymer donors and low bandgap NFAs which can utilize more photons and maintaining a small voltage loss 3,7. Different from the fullerene and its derivatives, NFAs normally have an acceptor-donor-acceptor (A-D-A) structure with a C = C linker between the donor and acceptor moieties to maintain the conjugated structure. However, the C = C bonds in the NFAs are vulnerable sites that are prone to react with low work function interlayers 8,9 and basic materials 10. Generally, many classical and highly efficient cathode interfacial materials (CIMs) such as polyethylenimine (PEI), poly-ethylenimine ethoxylated (PEIE) and poly[(9,9-bis(30-(N,N-diethylamino)propyl)−2,7-fluorene)-alt-2,7-(9,9-dioctyl-fluorene)] (PFN) contain amine groups in their structures. The lone-pair electron in amines can function as a nucleophile with NFAs through an addition reaction and eventually change the large-conjugated structure of the NFAs, resulting in failure of the photovoltaic characteristic 11,12 and stability of the corresponding device during the long-term operation. Considering the potential risk of efficiency loss arise from chemical structure altering of NFAs, the development of high-performance CIMs with improved chemical and structural stability is a feasible strategy to prolong device stability. Many efforts have been carried out to overcome this interfacial instability by developing more stable CIMs to minimize the reactivity of the amine groups in CIMs. Xiong et al. 9. proposed a method to protonate the amine group in PEIE to discourage the interfacial reaction and achieved a flexible NFA OSC with a power conversion efficiency (PCE) of 12.5%. Qin et al. 13 found chelation of PEI with Zn 2 (PEI-Zn) can be realized by addition of zinc acetate dihydrate into the PEI solution. This allows strong chelation between Zn 2 and amino groups, thus inhibiting the reaction between PEI and the IT-4F. In this way, chelation of metallic elements was shown to be another way to design and synthesize high-performance CIMs with good device efficiency and stability.

Among all the efficient CIMs, the alcohol-soluble small molecular are the most popular due to the convenient synthesis route synthesis and easy functional group modification. Bathocuproine (BCP) is the first reported organic CIM to facilitate electron transport in OSCs 14. Subsequently, multiple studies of BCP and its derivatives have been reported to further improving the device efficiency and stability, because a wide-bandgap CIM with a deep HOMO energy level is favorable for OSCs due to the sufficient electron transport. BCP is mainly hampered by its structural instability and chemical reaction with NFAs as has been reported previously 15. 1,10-Phenanthroline (Phen), with its rigid and planar chemical structure is a versatile chelating agent which can stabilize low-valent metals 16. Consequently, the design and development of morphologically stable CIMs based on Phen can simultaneously improve electronic transport and simplify their synthesis.

Interfacial engineering has been proven as an efficient strategy to improve the efficiency of OSCs. over, the highly efficient interfacial materials with suppressed chemical reactivity with active layer and inherent stability not only benefits the lifetime of single junction solar cells, but can also work well as an interconnecting layer (ICL) in OSC-based tandem solar cells (TSC) that enable a thermal post-treatment process for top OSC photon-absorption layer, which is a process that researchers commonly tried to avoid in previous reports 17,18,19. Herein, based on previous study of carbolong materials on solar cell field 20,21,22. we demonstrate two highly efficient, alcohol-soluble CIMs, a single-phenanthroline-carbolong (SPC) and a double-phenanthroline-carbolong (DPC), with the same Phen core connecting one or two carbolong complexes, respectively. Both SPC and DPC exhibit decreased HOMO and LUMO energy levels and enhanced electrical conductivity than BCP, which are beneficial for efficiency enhancement of the corresponding devices. A work function shift of the Ag cathode closer to the LUMO of the acceptor was also observed. As a result, the DPC and SPC CIL based devices achieve excellent efficiencies of 18.2% and 17.8%, respectively, which are higher than the control BCP-based device (17.4%). importantly, due to the strong electron-withdrawing property and the large steric-hindrance of DPC, the chemical reaction between CIL and acceptor (L8-BO in this work) is restrained. Meanwhile, the DPC with good structural stability can prohibit the diffusion of the photoactive material to the electrode for its robust structure. Therefore, the DPC OSC shows an enormous enhancement of device stability that retained 80% of initial efficiency (T80 lifetime) for 96 h after being heated at 85 o C while the BCP-based device fast decreased to almost 0% within only 1 h. Besides, DPC-based device maintained a T80 lifetime about 2170 h when kept in dark while the BCP contender device quickly dropped to 5% of its initial PCE within 195 h. over, the DPC-based OSC showed significantly improved illumination stability that can maintain 68% after being illuminated for 2200 h. than that, the DPC with improved photovoltaic performance and stability, can work well as an ICL for perovskite/OSC tandem solar cell and enable the top OSC cell undergo a thermal annealing post-treatment ultimately achieved a high efficiency of 21.7%. This work provides a universal methodology of CIMs design and synthesis utilizing the idea of chemical inserting between CIM and NFAs thus benefit for application in photovoltaic device.

Results

Materials synthesis and characterization

As outlined in Fig. 1, the compounds of SPC and DPC were synthesized according to an addition reaction of 3-ethynyl-1,10-phenanthroline (Phen-S1) or 3,8-bis(ethynyl)−1,10-phenanth-roline (Phen-D1) with a carbolong complex (S1), which yielded a productivity more than 90% in a one-step synthesis route. It is the electrophilic addition of carbyne by the alkyne under the synergistic effect of H 22. The structures of SPC and DPC were characterized by nuclear magnetic resonance (NMR) spectroscopy and electrospray ionization mass spectrometry (ESI-MS) (Supplementary Figs. 1–8). We successfully obtained the single crystal of SPC (Supplementary Fig. 9), and the detailed crystal data is provided in Supplementary Table 1. Similar to the structure of BCP, both SPC and DPC have a Phen core but connecting one or two carbolong complex units (Supplementary Fig. 10). Due to the strong electron-withdrawing properties and large steric hindrance of the carbolong unit, the photovoltaic properties and structural stability of both SPC and DPC have been greatly improved when compared with BCP that will be discussed later.

The photovoltaic properties of CIL can directly influence the efficiency of OSCs. Systematic studies were carried out to investigate the effect of the carbolong substitution on the photovoltaic properties of CIMs and compared them with BCP. Fig. 2a shows the normalized ultraviolet visible (UV-vis) absorption spectra of SPC and DPC. The absorption peak of SPC is located at 543 nm and the peak of DPC red shifted to 558 nm because of the added carbolong substitution. The optical bandgap (Eg) of these three materials can be obtained from the Tauc plot according to the following equation 23 : αhν = A(hν-Eg) 1/2. where A is a content, α is the absorption coefficient and hν is the photon energy. Linear fits of (αhν) 2 curves of BCP, SPC and DPC (Supplementary Fig. 11a) given Band gaps of 3.10, 2.03 and 1.81 eV, respectively. The detailed parameters are summarized in Table 1. The highest occupied molecular orbital (HOMO) energy levels of BCP, SPC and DPC are measured by ultraviolet photoelectron spectrometry (UPS) measurement (Supplementary Fig. 11b, c) and were determined to be −6.22, −6.48 and −6.50 eV, respectively. The lowest unoccupied molecular orbital (LUMO) energy levels of BCP, SPC and DPC obtained by the Eg and HOMO energy level which calculated to be −3.12, −4.45 and −4.69 eV, respectively. The simulated distribution of HOMO and LUMO orbitals was provided in Supplementary Fig. 12. There is strong π-delocalization between the Phen core and carbolong frameworks in SPC and DPC. The energy levels of each functional layer in the device are exhibited in Fig. 2b and Table 1, meanwhile the energy level of other layers are derived from previous reports 24,25. When compared with BCP, the LUMO energy levels of SPC and DPC decreased by 1.33 and 1.57 eV, respectively, closer to the LUMO energy level of L8-BO acceptor and hence benefit the electron transportation at the active layer/ETL interface. Besides, the HOMO energy levels of SPC and DPC CIL are slightly less than that of BCP which can more efficiently block the injection of holes from the active layer to the cathode thus suppressing the recombination. We summarized the energy levels of highly efficient NFAs, commonly used CIMs as well as metal electrodes that have been reported in recent years (Supplementary Fig. 13 and Supplementary Table 2). Both deep HOMO and LUMO energy levels of SPC and DPC are more suitable with the novel NFAs in current OSCs. For OSCs, the CIL is regarded as an exciton separation and charge transport layer at the cathode. To understand the carbolong substitution on conductivity of SPC and DPC which is directly relate to the device performance according to efficient electron transmission. The self-doping effect of CIMs were investigated by the electron spin resonance (ESR) spectroscopy that can been seen from Supplementary Fig. 14. We firstly investigated the sole component of BCP, SPC and DPC. Very weak signal around g value of 2 from unpaired electron were detected in BCP, SPC and DPC. To further resealing the self-doping effect happed between acceptor and CIM, we also tested the ESR spectra of L8-BO:CIMs. The sample was prepared by dissolving L8-BO and CIM with molar ratio of 1:1 in chloroform followed by drying in a vacuum chamber. From the result, the L8-BO:DPC inhabits the highest resonance peak, suggesting the most efficient electron transport when compared with L8-BO:SPC and L8-BO:BCP. Therefore, we measured the current-voltage (I–V) characteristic of sandwiched deice with structure of ITO/CIL/Ag as shown in Fig. 2c and Table 1. the direct current (DC) conductivity (σ) can be obtained from the slope of I–V plot according to the following equation 26 :

wherein A is area of device (0.046 cm 2 ), and d is the thickness of film. The σ values of BCP, SPC and DPC were 0.0013, 0.0027 and 0.0036 mS cm −1. respectively. The DPC exhibits the largest σ value indicating the highest vertical conductivity which is good for fast transporting the electron as soon as photogenerated carriers are separated.

To deeply insight into the completely different effect of BCP and DPC on the illumination stability of device, we carried out X-ray photoelectron spectroscopy (XPS) measurements to trace the signal of N 1 s orbital. In this measurement, we firstly tested the N 1 s signal of pure BCP or DPC CIL film without any photoaging as shown in Supplementary Fig. 21. The characteristic N 1 s peak of fresh BCP is located at 398.5 eV while DPC shifted to 399.5 eV due to the two carbolong units with strong electron withdrawing property on the structure 28. For the fresh BCP or DPC film that spin-coated upon L8-BO film as shown in Fig. 4b and c, the XPS peak of N 1 s are situated at 398.5 and 399.5 eV, respectively, which are same locations with the pure BCP and DPC film. After been illuminated for 2000 h, the N 1 s peak of DPC that covering upon L8-BO layer also show a stronger peak at 399.5 eV which is same location as pure DPC film. However, the peak of L8-BO/BCP film moved to 398.9 eV indicating that the chemical structural of BCP changed during the photon-oxidation process. The negligible influence of L8-BO on DPC CIL under long-term illumination can contribute to the slow PCE decay rate of DPC-based devices. Besides the better chemical stability of DPC which pacifies the interfacial reaction as discussed above, the DPC with its good structural stability benefits for the blocking of the diffusion of photoactive layer to metal electrode which is another efficiency damage issue occurring in OSCs 29. To further study the effect of long-time photo-degradation on the Ag electrode, we measured the surface morphology of Ag after the devices had been aged under light for 2000 h. After being photoaged for 2000 h, the edge SEM images of Ag coated upon BCP CIL reveal a large-scale breakdown (Fig. 4d, e) and multiple agglomeration points are shown in Fig. 4f, which is possibly related to the aggregation of active layers or metal diffusion 30. A large number of pinholes that found on the surface SEM images of BCP/Ag can seriously damage the efficiency of device and lead to an abnormal J–V curve 31. Compared with BCP/Ag, the surface of Ag covered by DPC shows better morphology with less degradation at the edges (Fig. 4g, h) and no agglomeration point or pinholes at the surface as shown in Fig. 4i. Therefore, the negligible reactivity and good structural stability of DPC contributes to the long-time illumination stability of the devices.

Exciton separation and charge transportation

From the statistics of the device photovoltaic parameters based on CIL free, BCP, SPC, and DPC (Supplementary Fig. 16), the efficiency of DPC-based devices mainly comes from the increase of JSC and FF which account for the efficient collection and extraction of negative carriers 32. We further confirmed it with steady-state photoluminescence (PL) measurements. The emission peak at 910 nm originates from L8-BO (Supplementary Fig. 22). As shown in Fig. 5a, D18:L8-BO blends covered by DPC CIL exhibit the largest PL quenching efficiency when compared with BCP and SPC, indicating the most efficient charge extraction and transportation process at the active layer/DPC interface. The relationship between photocurrent-density (Jph) and effective applied voltage (Veff) was tested to investigate the high performance of devices with DPC (Fig. 5b). Jph is calculated as Jph = JL − JD, where JL and JD are the current density under illumination and in the dark, respectively. Veff is determined by Vbi – Vapp, where Vbi is the built-in voltage and refers to the voltage at which Jph = 0 and Vapp is the applied bias voltage. The charge collection efficiency (ηc), taking into account both the charge transport in the D18:L8-BO active layer and transfer at the interface could be characterized by the ratio of Jph/Jph,sat under different values of Veff, where Jph,sat is the saturated photocurrent at high Veff, where the internal electric field is so high that all the photogenerated carriers are swept out to the electrode without recombination, and thus limited only by the absorbed photons. ηc of DPC-based device finally calculated to be 0.998 which is higher than the values of SPC (0.997) or BCP (0.996) based device, respectively, suggesting the better charge transport and collection in the DPC-based device which leads to higher JSC and FF. In order to further explore the exciton separation in devices with BCP, SPC or DPC CIM, we conducted transient photocurrent (TPC) measurement as shown in Supplementary Fig. 23. The fitted decay time of BCP, SPC and DPC-based devices are 0.55, 0.23 and 0.22 μs, respectively. The most reduced extraction time confirmed the superior charge extraction ability of DPC-based device. Fig. 5c shows the curves of JSC as a function of the incident light intensity (I) with the formula of JSC ∝ I α. in which the deviation of the ideality factor α = 1 indicates the degree of bimolecular recombination 33. From the result, more bimolecular recombination existed in the BCP and SPC-based device with lower α values of 0.983 and 0.992, respectively. For the DPC-based device, an α value of 0.999 reveals the high suppression of bimolecular recombination in the device.

The improved charge dynamics in the DPC-based device can be further confirmed by electrochemical impedance spectroscopy (EIS). The Nyquist plot of EIS measured within the range of 0 to 10 MHz in dark condition under VOC are shown in Fig. 5d and the fitted EIS data according to the equivalent circuit 34 (Supplementary Fig. 24) is listed in Supplementary Table 4. The fitted curves matched well with the original data. R1 accounts for ohmic losses at contacts is in series with charge transport resistance (R2) and recombination resistance (R3) 35. The DPC OSC exhibits the lowest R1 indicating the smallest contact resistance at the cathode interface. over, the value of R3 significantly increased from 616.1 Ω (BCP device) to 3040.0 Ω (DPC device), indicating the suppressed recombination process in the DPC-based device which is consistence with the improved FF and JSC performance.

Monolithic perovskite/organic tandem solar cells

Unlike in a regular structure OSC as mentioned above, CIL does not undergo any thermal annealing process. In TSCs with inverted OSC as rear cell, thermal annealing during the deposition of organic active layer will trigger the reaction between the active layer and the fragile ICL, thus leading to significant energy loss in generation and dissociation of excitons 28. Therefore, inverted OSCs have higher requirements for CILs with thermal and structural stability. Robust DPC material with low chemical activity fits well for inverted OSCs and TSCs, the superb thermal tolerance, structural stability, and feasible orthogonal solvent usage of DPC enables the integration to the ICL in TSCs. We fabricated a monolithic perovskite/organic tandem solar cell with a structure of FTO/ZnO/SnO2/CsPbI2Br/PTAA/MoO3/Ag/ICL /D18:L8-BO/MoO3/Ag, and the ICL we used here were DPC and BCP. The cross-section SEM image of TSC can be seen in Fig. 6a, where the proper controlled thickness of CsPbI2Br and organic bulk-heterojunction absorber facilitates the evenly distributed light absorption and current match of sub-cells in TSC device. For perovskite/OSC TSC, the ICL beneath active layer of rear cell should have a high optical transmittance to ensure more transmitted light can be utilized by rear cell. Therefore, we measured the transmittance of BCP and DPC film, with data depicted in Supplementary Fig. 25. Although BCP film has very high transmittance, the DPC film obtained with optimized concentration (1 mg/mL) shows a very high transmittance of more than 97% in the long-wavelength region from 400 nm to 1000 nm, which is good enough for the solar cell utilization. Consequently, the high transmittance of BCP and DPC can ensure adequate light-harvesting for photoactive layer of tandem solar cell. Then, we measured the conductivity of DPC and BCP-based ICL with or without a TA process under 85 o C. As shown in Fig. 6b, DPC-based ICL achieves a higher conductivity than BCP, which can be ascribed to the distinct superior electric property as shown in Fig. 2c. importantly, the conductivity of DPC ICL increased slightly while the BCP device remained unchanged after thermal annealing under 85 °C for 10 min. The improvement can be ascribed to the increased crystallinity and can serve better bridging the perovskite front cell and organic rear cell and as the recombination center.

The photovoltaic parameters of individual single-junction sub-cells are summarized in Supplementary Table 5. The CsPbI2Br device, which features an optical bandgap of 1.92 eV, was used to absorb photons with higher energy in tandem devices. Firstly, the BCP and DPC-based devices were prepared with an inverted structure of ITO/BCP (DPC)/D18:L8-BO/MoO3/Ag, that were exactly same as rear cell in the tandem device to fully simulate the performance. The result is shown in Fig. 6c and summarized in Supplementary Table 5. BCP device with an inverted structure only obtained a PCE of 3.5% which is much lower than BCP-based OSC with a conventional structure. As a result, the PCE of corresponding BCP-TSC only achieved 12.4%. On the contrary, give the credit to strong electron-withdrawing properties and large steric hindrance of the carbolong units, the DPC device with optimized concentration of 1 mg mL.1 delivered a VOC of 0.85 V, JSC of 22.85 mA cm −2 with the optimal PCE of 13.7%. importantly, the resulted DPC-TSC achieved an impressive PCE of 21.7% with a high VOC of 2.07 V, a JSC of 12.95 mA cm.2 and an astonishing FF of 80.8%. Fig. 6d presents the EQE spectra of DPC-based TSC measured sequentially applying the bias light with 550 nm short pass filter and 800 nm long pass filter. The evenly split spectra of front cell and rear cell generated well matched current owing to the precisely controlled thickness of absorber. Besides, a high average PCE of 20.8% that obtained from 30 cells in Fig. 6e indicates the high repeatability of DPC-based TSC. We further tested the thermal stability of tandem device, and the results are shown in Fig. 6f. Due to the suppressed chemical activity and inherent stability, the DPC-based device maintained a good stability during storage in N2 glovebox under 85 o C continues heating for 90 h, 80.0% of its initial PCE remained, while the BCP-based device loses its J–V characteristic after the same time. The high device performance and enhanced stability of DPC as ICL for tandem solar cells indicating the potential wide application of carbolong in the photovoltaic field.

Discussion

In this work, we have synthesized two organometallic compounds CIMs demonstrated by combining one (SPC) or two (DPC) carbolong metallic units with 1,10-phenanthroline core as CIMs producing highly efficient OSCs and TSCs. The synthesized CIMs with carbolong substituents exhibit enhanced electron-transport properties and modified work function capability for electrodes, resulting in a high device efficiency of 18.2% based on DPC CIL. importantly, the introduction of carbolong metallic units in DPC can greatly suppress the reaction with the C = C of nonfullerene acceptor material (L8-BO in this work) and can block the diffusion of photoactive materials at the cathode, which is commonly seen in other amine-containing CIMs. Due to the suppressed chemical activity and inherent stability, DPC maintained excellent device stability when compared to BCP-based device. The best DPC-based device exhibits a storage T80 lifetime of about 2170 h in an N2 atmosphere which is about 53 times longer than the BCP-based device. Meanwhile, the DPC can slow down the device degradation rate and can maintain 68% of its initial PCE after being aged under continuous illumination for 2200 h and retains 80% of its original efficiency after being heated at 85 o C for 96 h. DPC can work well as an interconnecting layer in perovskite/OSC tandem solar cells and achieved a high efficiency of 21.7% which is higher than that of BCP-based device. The DPC-based TSC also can maintain 80% of its initial PCE after being heated under 85 o C for about 90 h. The carbolong based CIM with efficient photovoltaic performance and a stable structure can ensure the long-time stability and high efficiency of OSCs based on both NFAs and tandem solar cells.

Methods

Materials and synthesis

Unless special statement, all materials directly use after purchase including: D18 (Derthon OPV Co LTD), L8-BO (Solarmer materials), BCP (Adamas) and PEDOT:PSS (CLEVIOS™ P VP AI 4083). Solvents were distilled under nitrogen from sodium/benzophenone (hexane, tetrahydrofuran, diethyl ether) or calcium hydride (dichloromethane, DCM). Other reagents were used as received from Aldrich Chemical Co. Column chromatography was performed on alumina gel (200–300 mesh), silica gel (200–300 mesh) or polystyrene gel (Bio-Beads TM S-X3 Support, 200–400 mesh) in air.

Characterization of materials

NMR spectroscopic experiments were performed on a Bruker Ascend III 400 ( 1 H, 400.1 MHz, 13 C, 100.6 MHz, 31 P, 162.0 MHz) spectrometer at room temperature. 1 H and 13 C NMR chemical shifts (δ) are relative to tetramethyl silane (TMS), and 31 P NMR chemical shifts are relative to 85% H3PO4. The absolute values of the coupling constants are given in Hertz (Hz). Multiplicities are abbreviated as singlet (s), doublet (d), triplet (t), multiple (m), and broad(br). High-resolution mass spectra (HRMS) experiments were recorded on Thermo Fisher Scientific Q-Exactive MS System. The theoretical molecular ion peak was calculated by Compass Isotope Pattern software supplied by Bruker Co. Elemental analyses were performed on a Vario EL III elemental analyzer.

All structures were optimized at the B3LYP 36,37,38 level of functional theory. Frequency calculations were performed to confirm the characteristics of all the calculated structures as minima. All these structures evaluated were optimized at the B3LYP/6–31 G level of DFT with an SDD basis 39 set to describe OS atom. All the optimizations were performed with the Gaussian 09 software package 40.

Compound SPC was collected on a Bruker APEX-II CCD diffractometer with Cu Kα radiation (λ = 1.54184 Å). Using Olex2 41. All the structures were solved using the ShelXT 42 structure solution program using the intrinsic phasing method, and all the structures were refined with the ShelXL 43 refinement package using least-squares minimization. Non-H atoms were refined anisotropically unless otherwise stated. Hydrogen atoms were introduced at their geometric positions and refined as riding atoms unless otherwise stated. All single crystals suitable for X-ray diffraction were grown from a solution of CH2Cl2 layered with hexane. Further details on the crystal data, data collection, and refinements are provided in Supplementary Table 1. The X-ray crystallographic coordinates for structures reported in this study have been deposited at the Cambridge Crystallographic Data Center (CCDC), under deposition numbers 2220750 (SPC), the Cambridge Crystallographic Data Center via www.ccdc.cam.ac.uk/data_request/cif. The detailed information as shown in Supplementary Data 1. The XPS measurement was tested by ULVAC PHI 5000 Versa Probe III with Al Kα radiation (1486.6 eV). UPS were measurement by d He I (21.22 eV) as the excitation source with an energy resolution of 50 meV.

Device fabrication and characterization

Single-junction OSC Fabrication: ITO-coated glasses (15 Ω sq.1 ) were sequentially cleaned by deionized water, acetone, and isopropanol in an ultrasonic bath. After drying, the ITO substrates were UV treatment for 20 min, PEDOT: PSS film was fabricated by spin-coating at 6000 rpm for 22 s then annealed at 150 o C for 10 min on hotplate. For the active layer, the D18 donor and L8-BO acceptor were mixed in CF solvent at a ratio of 1:1.2 with 0.5% (volume ratio) chloronaphthalene (CN) as an additive, the total concentration is 12 mg/ml. The solution was spin-coated on the ITO/PEDOT: PSS substrate at 3000 rpm for 35 s, then annealing at 100 o C for 10 min. For the CIL, the SPC or DPC was dissolved in methanol with different concentration without any cosolvent. The concentration of BCP is 0.5 mg/ml in methanol. All the CILs were fabricated at 2200 rpm for 30 s on the active layer. Finally, device fabrication was completed by thermal evaporation of a 100 nm Ag.

Perovskite/OSC Tandem Device Fabrication: For the single junction perovskite solar cell, s-ZnO layer was formed by spin coating ZnO sol–gel solution at 3000 rpm for 30 s, then annealing at 170 °C for 1 h. After that, SnO2 was spin coated on ZnO layer at 3000 rpm for 30 s, followed by annealing at 150 °C for 30 min. The CsPbI2Br precursor was spin coated on ZnO/SnO2 ETL in N2 filled glovebox via a two-step spin-coatin followed a gradient annealing process; the depositing procedure was set to be 1000 rpm for 10 s and 3500 rpm for 25 s. Chlorobenzene was dripped onto the rotating substrate 10 s prior to the end of the program. The samples were immediately transferred to a hotplate and sequentially annealed at 50 °C for 1 min and 240 °C for 1 min. PTAA with concentration of 10 mg mL −1 was spin coated on perovskite at 3000 rpm for 30 s. Finally, MoO3 and Ag electrode were thermally evaporated with controlled thickness of 10 and 100 nm, respectively. For BCP or DPC-based single junction invert OSC, BCP or DPC was deposited on ITO substrate at 2000 rpm for 30 s. The D18:L8-BO (1:1.2) blend film was deposited by using dynamic spin coating at 3000 rpm for 30 s, followed by annealing at 100 °C for 10 min in the case of thermal annealing device. Then, MoO3 and Ag electrode were thermally evaporated with controlled thickness of 10 and 100 nm, respectively. The ICL of MoO3 (≈10 nm)/Ag ( ≈ 1 nm)/BCP or DPC layer was formed by evaporating MoO3 and Ag; the BCP or DPC layer was spin coated at 3000 rpm for 30 s. Other procedures can be referred to the fabrication in single junction solar cell.

The current-voltage (J-V) characteristics were measured under AM 1.5 G illumination at 100 mW cm −2 with a solar simulator (Enlitech, Inc) in the glovebox and calibrated by a silicon cell (Hamamatsu S1133 color, with KG-5 visible filter). For J-V curve measurement, the active area is 0.046 cm 2. EQE measurements were conducted on devices under short-circuit conditions through a lock-in amplifier under illumination with monochromatic light from a xenon lamp (Enlitech, Inc). Mobility of hole and electron was measured accrording to a field-independent space charge limited current (SCLC) model following the Mott-Gurney law:

wherein J is current, μ is the mobility, ε0 is the permittivity of free space, εr is the relative permittivity of the material, d is the thickness and V is the voltage. The electron-only device structure is ITO/ZnO/L8-BO/CIL/Ag.

Photoluminescence measurement

Steady-state photoluminescence (PL) spectra of films were measured with an FLS920 spectro-fluorimeter (Edinburgh Instruments), whose light source system contains 450 W xenon lamp and a Glan prism. Spectrograph detection used Ge detector with reponse range from 800 to 1700 nm. The data was collected and analyzed by the connected F900 systems software.

Sability measurement

The devices for thermal-stability test were continuous heating under an 85 o C hotplate in glove box. The storage stability was tested in dark N2 atomospher. Illumination stabiliy was obtained by constantly exposing the device stored in the glove box to an LED light (1 sun). The device area is 0.046 cm 2 determined by the designed shadow mask calibrated by optical microscope. The start and end sweep voltage were.0.2 V to 1 V with a step of 0.01 V and a dwell time of 1 ms.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The authors declare that the source data generated in this study are provided in the Supplementary Information and Source Data file. All source data generated during the current study are available from the corresponding authors upon request. Source data are provided with this paper.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (22225504, 21975115, 51903116, 21931002), Shenzhen Fundamental Research program (JCYJ20190809163011543 and JCYJ20200109140812302), Guangdong Provincial Key Laboratory of Catalysis (2020B121201002), Guangdong Innovative and Entrepreneurial Research Team Program (2016ZT06G587), Shenzhen Sci-Tech Fund (KYTDPT20181011104007), and China Postdoctoral Science Foundation (No. 2021M701567). We also appreciate the assistance of SUSTech Core Research Facilities with compound characterization.

Author information

Authors and Affiliations

- School of Chemistry and Chemical Engineering, Harbin Institute of Technology, Harbin, 150001, China Xue Lai,

- Shenzhen Grubbs Institute and Department of Chemistry, Southern University of Science and Technology Shenzhen, Shenzhen, 518055, China Xue Lai,, Shiyan Chen,, Hanjian Lai,, Yunpeng Wang,, Yulin Zhu,, Hui Wang,, Jianfei Qu,, Haiping Xia Feng He

- Guangdong University Key Laboratory for Advanced Quantum Dot Displays and Lighting, and Department of Electrical Electronic Engineering, Southern University of Science and Technology, Shenzhen, 518055, China Xiaoyu Gu, Aung Ko Ko Kyaw

- Guangdong Provincial Key Laboratory of Catalysis, Southern University of Science and Technology Shenzhen, Shenzhen, 518055, China Haiping Xia Feng He

What can organic solar cells bring to the table?

OSCs expand the potential applications of solar technology, but there are still challenges to be overcome before large-scale deployment.

When you picture solar power, chances are you conjure up images of large solar panels spanning the length of a rooftop or a large solar farm out in a field. But what if you could put a solar panel in the sunroof of a hybrid car, on a tent or within the Windows of an office building? What if you could power a vaccine refrigerator in a remote place with a flexible solar panel that could be shipped in a mailing tube? These are just a few possible applications of a relatively new technology known as organic solar cells (OSCs) — new, at least, when compared with silicon solar technology, which has been around since the 1950s.

Like traditional silicon solar technology, OSCs turn the sun’s energy into usable electricity. But they are far more versatile than conventional solar photovoltaics. OSCs are lightweight and flexible and can be made to be semitransparent or in various colors. These qualities give them potential applications for textile, vehicle and building-integrated solar cells, and for creating power in areas where it does not exist.

Unique applications

While additional funding and research are needed to bring OSCs to the commercial market, experts agree they will play an important role in the future of solar technology. That said, they won’t replace or compete head-to-head with silicon solar cells. We shouldn’t expect to see expansive fields of OSCs, like those that generate gigawatts of power at silicon solar farms, says Seth Marder, a chemistry professor at Georgia Tech. Silicon solar is suitable for providing large-scale solar power, while OSCs have other unique strengths that guide its real-world applications.

Two unique features of OSCs are their thinness and flexibility. While a typical silicon solar cell is about as thick as the average width of a human hair, most OSCs are roughly a thousand times thinner. Because of their thinness and flexibility, OSCs can be fabricated on curved surfaces and flexible backings. For example, they can be patched or integrated into the fabric of tents, backpacks and even clothing. Most of these products are still under development and occupy a niche market, but they demonstrate the innovative creativity that OSCs provide. With OSC technology, the possibilities for where solar cells can be used has been greatly expanded beyond just rooftops and solar farms.

If 10 years ago you had told me we would have organic solar cells of 18% efficiency, I would have laughed.

OSCs also can be made transparent, semitransparent or in various colors. As a result, there are many potential applications for architectural use. For example, transparent OSCs could be integrated into Windows to generate energy from sunlight that otherwise might warm a room and contribute to higher air conditioning costs. Franky So, a materials science and engineering professor at North Carolina State University, offers yet another application: OSCs could be used in sunroofs to help power electric and hybrid vehicles.

Additionally, low up-front investment and potentially low product shipping costs make OSC technology accessible to communities in developing countries that lack access to an electrical grid and the financial means to build one. OSCs have a unique ability to bring power where power does not exist, explains Malika Jeffries-EL, an associate professor of chemistry at Boston University. In these instances, OSC technology could provide essential electricity in the smaller quantities needed for tasks such as lighting, charging cell phones and refrigerating medications and vaccines.

Another selling point of OSCs is that they are less energy intensive to manufacture than are silicon solar cells. Extremely hot furnaces — upwards of 2,700 degrees Fahrenheit — are needed to generate high purity silicon for silicon solar cells. By comparison, large-scale OSCs can be manufactured by simply printing the layers of the cell onto a backing in a process similar to that used to print newspapers. Because this process consumes less energy, OSCs have a significantly shorter energy payback time than silicon cells. In other words, OSCs require a shorter amount of time to generate the amount of energy it took to manufacture them.

How it works

The first organic solar cell was developed in 1958, but it wasn’t until the 2000s that OSCs saw a significant increase in efficiency. This improved OSC technology emerged from the field of organic light-emitting diodes, commonly known as OLEDs. OLED technology is used for many television and phone screens on the market today. In an OLED screen, a layer of organic molecules (molecules composed primarily of carbon and hydrogen atoms) emits light when an electric current is applied. OSCs work in essentially the opposite way — the layer of organic molecules generates an electric current when exposed to light.

An organic solar cell is made up of multiple layers of materials, one of which is the acceptor layer. When sunlight hits the cell, an electron is released from the layer of organic molecules, and the job of the acceptor is to pass that electron on to the electrode. This process causes a build-up of charge, which is what generates electricity.

With the development of non-fullerene acceptors, the efficiency of OSCs increased sharply. Graph courtesy of Felipe Larrain

Traditionally, the most commonly used acceptors in OSCs were materials based on fullerene — a molecule composed of 60 carbon atoms joined together in a structure that resembles a soccer ball. However, with fullerene acceptors the efficiency of OSCs was limited to around 10 percent. In other words, only 10 percent of the sunlight hitting the solar cell was converted into electricity. Researchers therefore set out to explore new types of acceptor layers as a means to increase OSC efficiency.

The breakthrough that permitted OSCs to achieve higher efficiencies was the development of non-fullerene acceptors (NFAs). With NFAs the efficiency of OSCs increased sharply — up to 18 percent in just a few years. This has brought OSCs to the lower end of the 18 percent to 22 percent efficiency of the average commercially available silicon solar cell. This uptick in efficiency has exceeded the expectations of many experts, some of whom began working in the field when the efficiency of OSCs hovered around just 3 percent. If 10 years ago you had told me we would have organic solar cells of 18 percent efficiency, I would have laughed, Marder says.

Barriers to overcome

There is still much work to be done before OSCs can be widely marketed. One of the biggest challenges is the solvents used in the manufacturing process. Most top-performing OSCs are made using chlorinated solvents, which present both health and environmental hazards. When scaling up OSC manufacturing, you have to consider the exposure of people who will be working in the manufacturing plants, says Bernard Kippelen, a professor of electrical and computer engineering at Georgia Tech. The research to date has focused largely on obtaining increasingly higher efficiencies, but as Kippelen says, we need an approach that goes well beyond just one number. To make OSCs a viable technology, the manufacturing process must be optimized to make it safer and more cost-effective.

Organic solar cells require a shorter amount of time to generate the amount of energy it took to manufacture them.

Another barrier to the mass production of OSCs is the difference between the efficiencies of individual cells tested under ideal lab conditions and the efficiencies that have been demonstrated for larger modules. Individual cells can have high efficiencies, but assembling multiple cells into modules, panels or arrays requires additional electrical connections that will decrease the efficiency. However, as Kippelen points out, such disparities are expected. It takes some time before the increases in cell efficiency are reflected in the efficiencies of modules coming off the manufacturing lines, he says. The same was true of silicon solar cells.

Funding for OSC research is another concern. In the United States, much of the funding for solar cell research comes from government agencies, such as the Department of Energy. However, according to Kippelen, A lot of funding sources kind of dried up to do research on OSC, due to the emergence of a rapidly expanding class of solar cells called perovskites. There has been a lot of excitement around the use of perovskites because their efficiency is even higher than silicon in some cases. However, even as funding for OSCs has decreased in the U.S., China continues to spearhead OSC research and development. The amount of work [on OSC research] in the United States is a tiny fraction of the amount of work in China,” Marder says. People in China are going full blast on this.

Reasons for optimism

Future world energy consumption will continue to rise, especially as developing countries aspire to the same benefits of on-demand energy production that developed countries enjoy. Researchers such as Marder, Kippelen, Jeffries-EL and So say OSC technology has the potential to play a unique and important role in the global transition toward renewable energy. The recent increase in OSC efficiency to 18 percent has many researchers working to advance this technology, and scientists are looking into tandem OSCs (which use two materials that absorb distinct wavelengths of sunlight) to capture even more energy. Some are hopeful that this development could increase OSC efficiency even further — up to 20 percent.

Kippelen calls for a long-term view of OSC technology. Solar technology is going to be around for a long time,” he says, “and I truly believe OSC, with time, will establish itself as a really important technology.

Editor’s note: Kellie Stellmach wrote this story as a participant in the Ensia Mentor Program. She is a graduate student pursuing her Ph.D. in chemistry at Georgia Tech. Her research is unrelated to the field of organic solar cells. While she has taken a class with Seth Marder, the interviews for this story were done before she was his student.

This story first appeared on: