Solar Air Conditioning / Solar Assisted Cooling : SAC Technologies

Consumption for air-conditioning of buildings is strongly increasing. There are several reasons for this, such as the increased thermal loads in buildings caused by electrical devices, the increased expectations of comfort regarding the ambient climate, as well as the architectural trend to utilise glazed surfaces.

Global HVAC demand to rise more than 6% annually through 2014

Industry study from Bharat Book Bureau / Freedonia. (May 2010)

According to the Energy Information Administration (EIA), space-heating and cooling in the commercial sector accounts for 40% of total energy consumption. In the residential sector this number rises to almost 70%. Conventional cooling systems utilise a compressor, which is usually electrically driven and hence energy-intensive to operate.

An alternative solution: Cooling with solar energy

Meeting these demands with solar energy is a particularly attractive option, due to the natural match between solar radiation availability and building cooling loads. On the basis of solar radiation and air-conditioning demand peaking at the same time during the day, it makes sense to resort to solar cooling and cover a considerable portion of the load with free energy derived from the sun.

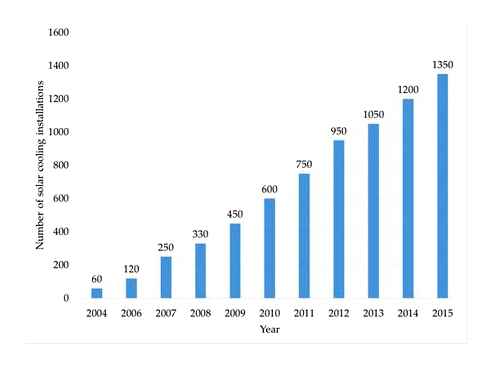

Nowadays solar cooling technologies are neither as well known, nor as widespread as they should be. They have not yet enjoyed a significant level of penetration into the air conditioning market even if in recent years hundreds of solar cooling systems have been installed worldwide, most with a cooling capacity above 30 tons. (100kW).

Domestic-sized units are also being developed. This is the current trend, where a number of manufactures are introducing low-power systems of less than 20kW capacity.

Air-conditioning with solar power, how it is done

Solar cooling installations generally consist of the components used in a conventional water heating system, i.e. solar collectors, storage tank, control unit, pipes and pumps plus a thermally driven cooling machine.

The solar collectors need to be a high-efficiency type, such as double-glazed, selective flat plate collectors or evacuated tube collectors.

In practice, solar collectors produce heat that is then fed into a thermally-driven chiller (cooling heat pumps) delivering refrigerant into a direct air-conditioning wall/ceiling unit. For large-scale, stationary applications, solar hot water is an excellent source of thermal energy to drive the chiller.

Click on the picture to enlarge the table.-

Electricity consumption is minimal. In a typical design for room air conditioning, 1 kilowatt (kW) of electricity can produce up to 10 kW of cooling performance. This is why the heat-driven, solar-assisted chillers have an excellent potential in the space air-conditioning businesses.

Thermally driven heat pumps utilize sorption phenomenon. Sorption heat pumps can be operated with different working pairs (e.g. lithium bromide/water, zeolite/water, salt/ammonia or metal/hydrogen) and employ different operating principles, which may be absorption, adsorption or chemisorption (chemical reaction).

Solar AC Technologies: Open and Closed Refrigerant Systems

Cooling can be provided using either a closed or an open refrigerant system.

Closed systems use either absorption (liquid sorbent) or adsorption (solid sorbent) chillers to provide chilled water. Solar heat is used to regenerate the sorbent by driving off the refrigerant. Systems using absorption chillers are the most common.

Open systems supply cooled and dehumidified air using a desiccant cooling system and solar heat is used to remove water from the desiccant. Most common systems are desiccant cooling systems using a rotating dehumidification wheel with solid sorbent.

Click on the picture to enlarge the table.-

️ The Heavy Environmental Cost of Air Conditioning

Americans spend a phenomenal amount of money on cooling their homes every year.

Energy.gov estimates that as much as 11 billion of our hard-earned salaries goes toward powering air conditioners.

Given that around 87 percent of us have air conditioners in our homes, it should be no surprise that the average cost to run it comes to almost 300 per household a year.

This figure represents around 12 percent of the total domestic energy expenditure.

Not only are air conditioning costs hurtful to our personal finances, but their high energy demands are also terrible for the environment.

The heavy energy use of air conditioning in the United States alone contributes an estimated 140 million tons of carbon dioxide annually.

At a time when working toward becoming carbon-neutral is at the forefront of domestic and international policy (this includes you as well, Canada…).

The massive energy consumption required for the simple task of keeping us cool in our homes needs to be addressed sooner rather than later, and solar air conditioners could be the solution.

️ How Do Solar-Powered Air Conditioners Work?

There are several different solar air conditioners, although many of these are not yet available in consumer markets.

Nonetheless, three types have become common in residential buildings in the last few years:

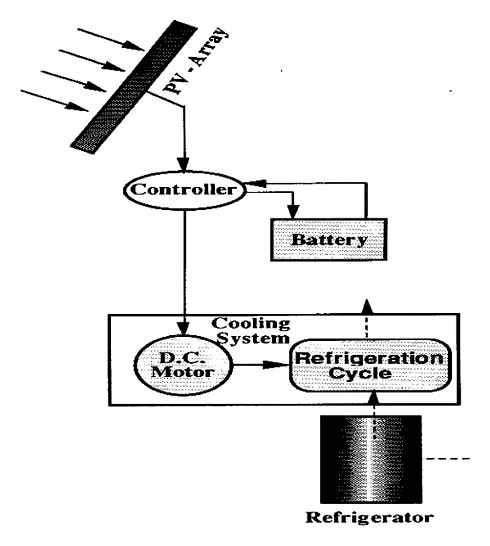

Solar Photovoltaic (Solar PV) Air Conditioners

These systems capture the sun’s solar energy using solar photovoltaic panels, usually mounted on a building’s roof.

The solar PV panels convert this solar energy into electricity to power all the constituent parts of a traditional split system.

The electricity that is not used is stored in a battery array for later use.

In addition, some hybrid air conditioner systems are connected to the electricity grid to provide an extra boost if the sun is not strong enough to charge the batteries.

Solar Thermal Systems

These systems employ a plate to capture solar energy from the sun’s rays.

See what three degrees of global warming looks like

This energy then directly works to turn an electric generator to power the compressor responsible for the refrigeration process in the air conditioning system.

Solar thermal systems use electricity from the grid to run the fans and the electric control panel.

However, this system is quickly falling out of fashion since they are less energy-efficient than solar photovoltaic systems.

Absorption Chillers

These systems use solar power from solar panels to drive the fan and compressor motor in systems that use evaporation and condensation to generate cool air.

Absorption chillers can run off batteries that solar panels have charged.

️ Are Solar-Powered Air Conditioning Systems Effective?

It may come as a surprise to you to learn that solar-powered air conditioning systems work just as well as conventional ones.

As long as you have enough sunlight (which will normally be the case since the system is only likely to be in use on a hot, sunny day anyway), a solar air conditioning system is equally effective at cooling an indoor space as a mains electric powered system.

In the rare event that you need to turn on the air conditioning on a cloudy day, solar air conditioner systems use a battery array for power.

The batteries in this array are charged with the excess energy collected by the solar panels on a hot day.

GJU System Description

3.1. Description of the Installation Site

The existing solar heating and cooling system was installed on the rooftop of building C in the campus of the German Jordanian University (GJU) in Jordan. GJU is a public university with around 5000 students, located near Madaba, Jordan. The absorption system under consideration is used to support the already-existing conventional compression system for Building C. The cooling capacity of Building C is equal to 700 kW and the share of H2O-LiBr was planned to be around 11% of the total cooling capacity, i.e., 160 kW. Building C consists of four levels and a basement with a total floor area of about 7500 m 2. The ground and the third floors consist mainly of laboratories and offices. The first and the second floors consist mainly of education rooms in addition to the academic staff offices.

3.2. Meteorological Data

The Photovoltaic Geographical Information System (PVGIS) tool was used to generate Typical Meteorological Year (TMY) data of solar radiation, temperature, and other meteorological data [25]. The data was provided by the typical meteorological year (TMY2) format containing hourly global and beam radiation data in addition to ambient temperature and sunshine duration values. The considered period for the data that was exported was from 1991–2010. Figure 3 and Figure 4 show the metrological data (daily ambient temperature and daily average global and diffuse radiation in June 2015) in the site over a period of a year.

The air temperature data for year 2015 in Madaba is presented in Figure 3. Madaba has an inland climate with large air temperature fluctuations across the seasons. In typical summer months (May–September), the highest air temperature normally occurs in June and between 12:00 and 14:00 where the air dry bulb temperature could reach 40 °C. The solar radiation normally reaches its peak value of around 1030 W/m 2 between 9:00 and 15:00, as shown in Figure 4.

3.3. System Description

The solar heating and cooling system was installed on the rooftop of building C at the GJU campus. The solar heating system consists of 30 solar collector arrays each with five modules connected in series. Each module (model CPC1518) has 18 evacuated tube collectors with compound parabolic collector (CPC) geometry. The aperture total surface area of the solar field was 450 m 2 and the collectors were oriented to face the south with a tilt angle of 45°. Figure 5 shows the solar collector field installed on the rooftop of Building C at the GJU campus.

The solar field is supplying the absorption chiller with water at 85 °C, this amounts to 44 MWh seasonal thermal energy for the absorption chiller of 250 MWh produced by the collectors. Four heat storage tanks each with a volume of 3.5 m 3 were integrated to the solar heating system. One of the storage tanks is used for domestic hot water in building C and the other three hot water storage tanks were connected to the absorption chiller’s generator. The solar hydraulic system is equipped with hot water pumps for each storage tank, two gas boilers (380 kW total capacity), and a dry cooler to remove excess heat.

The conventional cooling system consists of two air cooled multistage compression chillers, 700 kW each (one duty/one stand-by), and one of them can also work as a heat pump which operates only if the heating load reaches beyond the capacity of the solar field and the two boilers in cold winter days when there is no or minimum solar energy gain. The evaporator of the air-cooled multistage compression chillers provides chilled water in summer at a given set value for the chilled water outlet temperature, this temperature is set at 9 °C. The used refrigerant is R134a and is cooled down in an air-cooled condenser.

A 160 kW single-stage H2O-LiBr absorption chiller developed by the Technical University of Berlin was used to assist the conventional cooling system. The system was designed in a way that it does not interfere negatively with the existing compression system and operates in a way that it can be started and stopped independently from the old system. It was designed to cool a part of the airstream exiting the building down to 16 °C contingent on the solar energy gain. Hot water from the solar field enters the generator with a volume flow rate of 3.3 L/s. The heat sink for the condenser and the absorber is cooled with a water-stream leaving a 300-kW dry cooler with a volume flow rate of 12 L/s and temperature range between 30 to 40 °C. The evaporator provides chilled water with a volume flow rate varies between 3.5 to 8 L/s and temperature between 8 and 10 °C, depending on the generation water temperature. The major components of the absorption refrigeration system are two large containers, the low-pressure tank, and the high-pressure tank. The unit contains the four copper tube heat exchangers: evaporator, absorber, generator, and condenser. The external circuits for the chilled, cooling, and heating water were connected to the four copper tube heat exchangers.

Economic Feasibility

This economic study is intended to evaluate the overall economic viability in-depth. The key financial indicators used for the evaluation include Present Worth (PW), Payback Period, and Internal Rate of Return (IRR).

The PW method is the equivalent worth of all cash flows relative to some base or beginning point in time dubbed the present. That is, all cash revenues (incomes, saved energy, reduced CO2 emissions) and expenses (auxiliary power consumption, maintenance) are discounted to the present point in time at an interest rate [26]. A positive PW for the absorption cooling system will mean that the project is feasible and a profit over the minimum amount required will be achieved. To find the PW as a function of interest rate ( i %) of the cash inflows and outflows, the future amounts need to be discounted to the present by applying Equation (1) [27]. To discount future amounts to the present by using the interest rate over the appropriate study period, we used the following:

where ( i %) is the effective interest rate; ( k ) is the index for each compounding period 0 ≤ k ≤ N ; ( Fk ) is future cash flow at the end of period ( k ); ( A ) is the end-of-period cash flows in a uniform series continuing for a specified number of periods, starting at the end of the first period and continuing through the last period; and ( N ) is the number of compounding periods in the study period. In this study, N was set to 25 years which represents the life expectancy of the system and the interest rate which was set to i = 6%.

Annual expenses include the maintenance costs and the operating energy and water costs. For maintenance costs, standards like the Association of German Engineers (VDI) 2067 use 2% of the investment costs. Chiller manufacturers calculate maintenance costs by 1% of the investment costs. For large thermal chillers, companies offer constant cost maintenance: the costs vary between 0.5% for large machines (up to 700 kW) up to 3% for lower-power machines [28].

The payback period is the time required to recover the total investments by profit gaining. The payback period can be calculated by setting PW to 0. The simple payback period, θ, ignores the time value of money and all cash flows that occur after θ ( θ ≤ N ) and calculates the number of years required for cash inflows (Revenues R) to just equal cash outflows (Expenses, E). For this study, where initial investment occurs at time 0, the simple payback period is given in Equation (2) [27]:

In addition, the discounted payback period, θ ′ ( θ ′ ≤ N ), is calculated so that the time value of money is considered, as given in Equation (3) [27]:

4.1. Absorption Chiller Monitoring Results

The absorption chiller was monitored on several sunny summer days between May and July 2015. The cooling capacity and the thermal COP as a function of generation temperature ( Tg ) are shown in Figure 7 [29]. As shown in Figure 7, the cooling capacity varies and the maximum value reached about 30 kW with a mean daily generator temperature reaching values not higher than 80 °C. The thermal coefficient of performance is defined as the ratio of the cooling achieved in the evaporator of the absorption chiller to the driving heat applied to the generator. The COP of the absorption chiller varied significantly depending on the operating conditions. Low COP values were observed, varying between 0.09 to 0.54 compared to 0.79 as claimed by the manufacturer regarding of the operating conditions. The absorber and condenser mean daily temperature is between 24 °C and 38 °C with maximum ambient air temperatures reaching 41 °C. The mean daily evaporator temperature is between 8 °C and 15 °C.

Active Cooling of a Photovoltaic (PV) System (12% annual energy production)

The main result to investigate is the observed cooling capacity of just 18.7%, at maximum of the nominal cooling capacity value (160 kW). in addition, an average thermal COP of less than 0.3 can be observed. An explanation was listed by [29], who attributed this to the operation of the absorption chiller on non-demanding days (the University is closed on Fridays), the frequent operation of the solar dry cooler, and some control and instrument issues.

4.2. Cost and Tariffs

In order to determine the economic feasibility of the absorption chiller system, an estimation of the various components of the system was performed. A spreadsheet was tailored specifically to the absorption chiller system to perform the economic mathematical analysis. Various parameters were taken into account through the economic calculations. The system cost is defined through the cost of the absorption chiller according to the cooling capacity per watt, and the cost of the auxiliary component in the local market. Figure 8 shows the component share of the total cost.

As shown, the solar field has the highest cost of the solar cooling system with a share of 42%. The solar field at GJU was overdesigned regarding the supply of hot water to the generation of the weak H2O-LiBr solution, since the solar collector is also used for heating domestic hot water for Building C. In addition, the solar field was overdesigned to ensure that the chiller was working with a COP of 0.79 regardless of the outlet conditions. The installation and the operational cost are considerably lower as a result of low local wages in Jordan compared to developing countries.

Conclusions

Using solar power for the cooling and heating of buildings is a milestone in the search for environment-friendly technologies in the energy sector. Four solar absorption cooling systems with a nominal cooling capacity of 530 kW were installed in four sites in Jordan. The FOCUS of the research was on the pilot system at the German Jordanian University campus. The system has a capacity of 160 kW for cooling and a 50 kW for heating. With the installed systems, Jordan is the first developing country to use solar thermal energy to cool buildings. The aim of these systems was not only to reduce cooling power consumption, but also to serve as a reference for researchers and experts in absorption chillers, as it is the first of its kind to be implemented in Jordan, the region, and among developing countries. An economic feasibility study was carried out for the absorption system taking the environment effect of the reduction of CO2 emissions into account. This study was based on an evaluation of the solar thermal cooling system within four months of operation between May and July 2015.

The system was economically evaluated based on the observed cooling capacity results with a COP of 0.32, and compared with the claimed COP of 0.79 regardless of the operating conditions. Several techniques were implemented to evaluate the overall economic viability in-depth such as present worth value, internal rate of return, payback period, and levelized cost of electricity. The aforementioned economic studies showed that the absorption cooling system is deemed as not feasible for the observed COP of 0.32 over a lifespan of 25 years. The net present value was equal to −137,684 JD and there was a payback period of 44 years, which exceeds the expected lifespan of the project. Even for an optimal operation of COP = 0.79, the discounted payback period was equal to 23 years and the LCOE was equal to 0.65 JD/kWh.

The survey shows that there are several weaknesses for applying solar thermal cooling in developing countries, such as the high cost of these systems and, more significantly, the lack of experience for such systems. The solar thermal cooling systems currently installed in Jordan were either planned, built, and monitored by companies that specialize in solar thermal cooling, or were scientifically supported by a research institution and they were being evaluated via monitoring at the beginning of their operation.

From this perspective, the solar thermal cooling systems currently installed are not the technologically-possible optimum. There is significant potential for reducing costs and/or increasing performance through technological improvements mainly at the system level for overall system optimization. The introduction of a more advanced control through the absorption chiller components will increase operational efficiency, improve the cooling capacity, and contribute to the reduction of CO2 emissions. The main component in solar thermal cooling systems is the chiller and the most relevant controlled parameter is the hot water inlet temperature and mass flow. Optimization between high water temperature to the generator should be achieved, to increase the cooling capacity of the absorber, while preventing possible pump damage in the case of crystallization. The improvement of this advanced technology requires higher level of process control and professional expertise.

Author Contributions

Conceptualization, M.J.; methodology, M.J. and M.A.-A.; formal analysis, M.J. and A.A.; investigation, M.J. and A.A.; resources, N.B. and M.A.-A.; data curation, M.A.-A. and A.A.; writing—original draft preparation, M.J. and N.B.; writing—review and editing, M.J., M.A.-A. and Z.D.; supervision, M.J. and N.B. All authors have read and agreed to the published version of the manuscript.

- ASHRAE. ASHRAE 62-2001, Ventilation for Acceptable Indoor Air Quality ; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2001. [Google Scholar]

- Öberg, V.; Goswami, D.Y. Experimental Study of the Heat and Mass Transfer in a Packed Bed Liquid Desiccant Air Dehumidifier. J. Sol. Energy Eng. 1998, 120. 289. [Google Scholar] [CrossRef]

- Sayed, M.A.A.E.D.A.; Fikry, M.A. Impact of Glass Facades on Internal Environment of Buildings in Hot Arid Zone. Alex. Eng. J. 2019, 58. 1063–1075. [Google Scholar] [CrossRef]

- Huang, L.; Zheng, R. Energy and Economic Performance of Solar Cooling Systems in the Hot-Summer and Cold-Winter Zone. Buildings 2018, 8. 37. [Google Scholar] [CrossRef][Green Version]

- Martínez, P.J.; Martínez, P.; Soto, V.M.; Bujedo, L.A.; Rodriguez, J. Design of a 35 KW Solar Cooling Demonstration Facility for a Hotel in Spain. Appl. Sci. 2020, 10. 496. [Google Scholar] [CrossRef][Green Version]

- Pesaran, A.A.; Neymark, J. Potential of Solar Cooling Systems for Peak Demand Reduction. National Renewable Energy Laboratory (NREL): Golden, CO, USA, 1995. [Google Scholar]

- Kalkan, N.; Young, E.A.; Celiktas, A. Solar Thermal Air Conditioning Technology Reducing the Footprint of Solar Thermal Air Conditioning. Renew. Sustain. Energy Rev. 2012, 16. 6352–6383. [Google Scholar] [CrossRef]

- Calm, J.M. Emissions and Environmental Impacts from Air-Conditioning and Refrigeration Systems. Int. J. Refrig. 2002, 25. 293–305. [Google Scholar] [CrossRef]

- Ma, Y.; Saha, S.; Miller, W.; Guan, L. Comparison of Different Solar-Assisted Air Conditioning Systems for Australian Office Buildings. Energies 2017, 10. 1463. [Google Scholar] [CrossRef][Green Version]

- Henning, H.-M.; Döll, J. Solar Systems for Heating and Cooling of Buildings. Energy Procedia 2012, 30. 633–653. [Google Scholar] [CrossRef]

- Jaradat, M.; Al-Addous, M.; Albatayneh, A. Adaption of an Evaporative Desert Cooler into a Liquid Desiccant Air Conditioner: Experimental and Numerical Analysis. Atmosphere 2019, 11. 40. [Google Scholar] [CrossRef][Green Version]

- Rafique, M.; Rehman, S.; Alhems, L.; Ali Shakir, M. A Liquid Desiccant Enhanced Two Stage Evaporative Cooling System—Development and Performance Evaluation of a Test Rig. Energies 2017, 11. 72. [Google Scholar] [CrossRef][Green Version]

- Niemann, P.; Richter, F.; Speerforck, A.; Schmitz, G. Desiccant-Assisted Air Conditioning System Relying on Solar and Geothermal Energy during Summer and Winter. Energies 2019, 12. 3175. [Google Scholar] [CrossRef][Green Version]

- Narayanan, R.; Halawa, E.; Jain, S. Dehumidification Potential of a Solid Desiccant Based Evaporative Cooling System with an Enthalpy Exchanger Operating in Subtropical and Tropical Climates. Energies 2019, 12. 2704. [Google Scholar] [CrossRef][Green Version]

- Henning, H.-M.; Motta, M.; Mugnier, D.; Mazzarella, L.; Rolloos, R.; Mendes, J.F.; Carvalho, M.J.; Schossig, P.; Kohlenbach, P.; Besana, F.; et al. Solar Cooling Handbook: A Guide to Solar Assisted Cooling and Dehumidification Processes. 3rd ed.; Ambra: Vienna, Austria, 2013. [Google Scholar]

- Choudhury, B.; Saha, B.B.; Chatterjee, P.K.; Sarkar, J.P. An Overview of Developments in Adsorption Refrigeration Systems towards a Sustainable Way of Cooling. Appl. Energy 2013, 104. 554–567. [Google Scholar] [CrossRef]

- Halon, T.; Pelinska-Olko, E.; Szyc, M.; Zajaczkowski, B. Predicting Performance of a District Heat Powered Adsorption Chiller by Means of an Artificial Neural Network. Energies 2019, 12. 3328. [Google Scholar] [CrossRef][Green Version]

- Dieng, A.O.; Wang, R.Z. Literature Review on Solar Adsorption Technologies for Ice-Making and Air-Conditioning Purposes and Recent Developments in Solar Technology. Renew. Sustain. Energy Rev. 2001, 5. 313–342. [Google Scholar] [CrossRef]

- Shirazi, A.; Taylor, R.A.; Morrison, G.L.; White, S.D. Solar-Powered Absorption Chillers: A Comprehensive and Critical Review. Energy Convers. Manag. 2018, 171. 59–81. [Google Scholar] [CrossRef]

- Ghafoor, A.; Munir, A. Worldwide Overview of Solar Thermal Cooling Technologies. Renew. Sustain. Energy Rev. 2015, 43. 763–774. [Google Scholar] [CrossRef]

- Weiss, W.; Spörk-Dür, M. Solar Heat Worldwide. Global Market Development and Trends in 2017. Detailed Market Figures 2016. Available online: https://www.iea-shc.org/Data/Sites/1/media/events/webinars/2018-06-12/shc-market-and-industry-trendswweiss.pdf (accessed on 5 March 2020).

- Altarawneh, I.S.; Rawadieh, S.I.; Tarawneh, M.S.; Alrowwad, S.M.; Rimawi, F. Optimal Tilt Angle Trajectory for Maximizing Solar Energy Potential in Ma’an Area in Jordan. J. Renew. Sustain. Energy 2016, 8. 033701. [Google Scholar] [CrossRef]

- Salahat, M.A.; Al-Qinna, M.I. Rainfall Fluctuation for Exploring Desertification and Climate Change: New Aridity Classification. Jordan J. Earth Environ. Sci. 2015, 7. 9. [Google Scholar]

- Global Solar Thermal Energy Council. Available online: https://www.solarthermalworld.org/news/jordan-four-demonstration-plants-solar-air-conditioning-commissioned (accessed on 2 January 2020).

- Photovoltaic Geographical Information System (PVGIS). Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/tools.html#MR (accessed on 14 January 2020).

- Hoskins, C.G. Benefit-Cost Ratios Versus Net Present Value: Revisited. J. Bus. Financ. Account. 1974, 1. 249–264. [Google Scholar] [CrossRef]

- Sullivan, W.G.; Wicks, E.M.; Koelling, C.P. Engineering Economy. 16th ed.; Pearson/Prentice Hall: Upper Saddle River, NJ, USA, 2014. [Google Scholar]

- Eicker, U.; Pietruschka, D. Design and Performance of Solar Powered Absorption Cooling Systems in Office Buildings. Energy Build. 2009, 41. 81–91. [Google Scholar] [CrossRef]

- Paitazoglou, C.; Petersen, S. Solar Cooling for Industry and Commerce Absorption Chiller for a Solar Cooling System in German Jordan University (GJU) ; Institute of Energy Engineering, Department of Energy Conversion: Berlin, Germany, 2015. [Google Scholar]

- Jordanian Ministry of Environment. Jordan’s Third National Communication on Climate Change 2014; Amman, Jordan. Available online: https://unfccc.int/resource/docs/natc/jornc3.pdf (accessed on 1 March 2020).

- Jordanian Ministry of Energy and Mineral Resources. Energy Annual Report in 2016; Amman, Jordan. Available online: https://www.greengrowthknowledge.org/sites/default/files/downloads/policy-database/JORDAN%29%20The%20Ministry%20of%20Energy%20and%20Mineral%20Resources%2C%20Annual%20Report%202016.pdf (accessed on 1 March 2020).

Share

A group of scientists from the Imam Abdulrahman Bin Faisal University, in Saudi Arabia, has assessed the performance of several cooling techniques in solar PV systems subject to the country’s harsh environmental conditions.

The researchers’ analysis embraced passive cooling systems based on a heat sink or a heat sink embedded into phase change materials (PCMs), as well as active cooling relying on micro-flat heat pipes, either immersed or not immersed in an immersion fluid.

The passive technologies were assessed under two different configurations: an 11%-efficient polycrystalline solar module with a power output of 15 W, equipped with six aluminum heat sinks on the back panel; and the same panel equipped with heat sinks placed into a highly thermally conductive aluminum container filled with TPM350, which is a phase change material offering a high thermal conductivity and melting at 50 degrees Celsius. In all configurations, the solar panels were tilted at 25 degrees and south-oriented. Measurements took into account output power, the surface temperature of the modules, and power conversion efficiency.

Active cooling was considered in two forms: a system consisting of a row of four heat pipes cooled by flowing water and place onto the back of the panel; and another one consisting of four heat pipes immersed in a box of liquid, as liquid bulk, integrated with the back of the solar panel. “This technology is interesting for cooling purposes because it uses buoyancy flow of liquid and evaporative cooling in the heat pipes, as a means of transferring thermal energy,” the scientists explained, referring to the second system and noting that three different liquids, such as engine oil, ethylene glycol, and regular water, were tested.

Popular content

The two passive techniques were found not to be performant enough to ensure proper cooling. That technique with the simple heat sinks was able to lower the module operating temperature by 10 degrees Celsius, on average; and that based on the PCM was able to guarantee sufficient cooling only for the first two hours. “When melting was completed, the PCM became ineffective, allowing the panel temperature to rise sharply, becoming greater than that of the uncooled panel due to the thermal resistance of the PCM,” the Saudi group stated, adding that a PCM with a higher melting point should be utilized.

As for the active system, the most effective was that based on four heat pipes immersed in water, which was able to reduce the panel temperature by up to 53%; followed by those immersed in ethylene glycol, which results in a 48% reduction; and those immersed in engine oil, which lowered the module temperature by 25%. The lowest percentage – 21% – was obtained by the row of four heat pipes cooled by flowing water. “Lower panel temperatures and higher open-circuit voltages at the solar panel terminals were found if the panel was actively cooled using heat pipes immersed in regular water,” the academics emphasized. “In this configuration, the voltage increment was 13%, relatively compared to the uncooled panel configuration.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Share

Emiliano joined pv magazine in March 2017. He has been reporting on solar and renewable energy since 2009.