NREL First Solar Celebrate Nearly 30 Years of Collaboration on Cadmium Telluride (CdTe) Solar Cell Research

The National Renewable Energy Laboratory (NREL) has more than 550 unique, active partners. One such partner is First Solar Inc. — a relationship that dates back to the early ‘90s. NREL and First Solar, then called Solar Cells Inc., have been collaboratively breaking ground on thin film solar technology for more than two decades, helping NREL fulfill its goal as a Department of Energy (DOE) national laboratory of commercializing technology through partnerships, and contributing to First Solar’s success in development, manufacturing, and operation of photovoltaic (PV) power plants with technology that still bucks industry trends.

In early July, First Solar made headlines when it announced its intention to construct a 680 million solar panel manufacturing factory in Ohio, bringing with it an estimated 500 jobs. The announcement came just seven months into the inaugural year of the Biden administration, whose intersecting priorities to “build a modern, sustainable infrastructure and an equitable clean energy future” and “ensure the future is ‘made in all of America’ by all of America’s workers” have been well supported by Secretary of Energy Jennifer Granholm.

NREL is on the job, working consistently to enable such a future for nearly 45 years. When Solar Cells Inc. came along in the early ‘90s, the collaboration centered around the reliability, stability, and efficiency of the thin film cadmium telluride (“CdTe” for short) technology that it was using in its solar panels, also called modules. Then and now, the vast majority of solar modules are of crystalline silicon construction instead of cadmium telluride.

First Solar, an NREL research partner, has installed a small PV array used as part of NREL Energy Systems Integration research at the laboratory’s National Wind Technology Center. Photo by Dennis Schroeder, NREL.

The Early Days of the NREL–First Solar Partnership

In 1991, NREL was designated a national laboratory by President George Bush and renamed from its original title, the Solar Energy Research Institute. It was a different time, and unique approaches were taken with research related to CdTe technology.

NREL Group Manager of Materials Reliability and Durability Teresa Barnes said, “in those early times, it was scrappy little startup companies and it was a bunch of old friends working together. The CdTe community has always been very, very small. It was primarily in the U.S., and it was a much smaller research community than any other solar technology that I’ve ever worked in.”

Larry Kazmerski, a retired NREL senior scientist who headed materials and characterization for solar research at NREL at the time, said, for the duration of his time working on Solar Cells Inc. projects, there was never a nondisclosure agreement in place. It was just trust.

“You have to realize they didn’t come to NREL and say, ‘Hey we have a problem. Can you solve it?’” he said. “They would bring people out, and there would be discussion, and people would be looking at it in the lab together. It was a fairly open policy. They could come in and work together without much of a problem.”

Kazmerski saw a larger dependence on NREL, especially in the solar PV area with DOE, industries, and universities. It was more of a partnership of all players. During his time at NREL, Kazmerski recalled two NREL researchers who played key roles in moving CdTe research forward. One was Tom Surek, who pushed university, industry, and national laboratory partnerships, and who Kazmerski called the kingpin of the PV program management side. The other was Ken Zweibel, who brought his physics degree to the program management side of the house and was key in selling the laboratory on the value of CdTe. Kazmerski said they were blessed with program managers who were highly technical.

Reliability of CdTe solar cells was critical early on. Kazmerski said First Solar did not want to release anything until it was ready. They knew they had to have reliable modules. They tested everything to death and worked with NREL to validate efficiency and reliability. Barnes said First Solar is one of the best in the business for understanding reliability and durability, and NREL has learned a lot from the partnership and how it affects product development.

In fact, NREL is still learning from that early success today, thanks to one especially noteworthy achievement that planted roots two and a half decades ago. Twenty-five years ago, NREL installed a 0.6 kW Solar Cells Inc. PV system with 12 modules for a long-term test at the Outdoor Testing Facility. Those modules are still operating today.

Dirk Jordan, a senior engineer at NREL who studies the long-term performance of PV systems and analyzes the physics and chemistry of changes, said, “it’s the longest running system we have. It showed the degradation of a pretty reasonable 0.5% per year, which is in line with what silicon systems do.”

A First Solar 1.5-kW array composed of 80-W CIS modules is undergoing long-term reliability testing at NREL’s Outdoor Test Facility (OTF). Photo by Harin Ullal, NREL.

A Few Key Milestones in the Journey

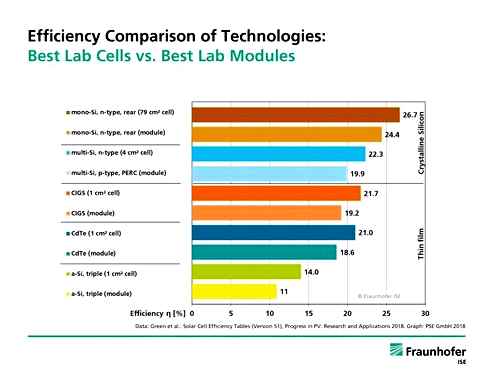

NREL and First Solar have crossed a series of thresholds together and hit numerous milestones along the way. NREL Director of the Power Systems Engineering Center Ben Kroposki said producing a CdTe cell that converted light to electricity with 10% efficiency was a major accomplishment Further research and development has led to today’s CdTe solar cells with efficiencies above 20%.

“When they were first coming out, they did not have very high-efficiency modules, but in working with them — and this was pretty early on — they always had a good idea of how to mass produce panels where they were basically making glass and depositing the CdTe on the glass,” he said. “They had a breakthrough working with some of the materials people at NREL that pushed efficiencies over 10%. That’s one of the big milestones: once they crossed over 10% efficiency and could start mass producing using their production techniques. That was a game-changer for these large-scale systems.”

Scalability has always set the First Solar partnership apart. A partnership goes two ways and where NREL was able to help test, validate, and provide fundamental research for First Solar, First Solar was able to teach NREL a thing or two as well.

“I think First Solar is always our example of how important it is to have a really manufacturable, scalable, steady process and to the importance of reproducibility,” Barnes said. “Because they got so good at scaling those results as they came through, they can now take that latest and greatest and scale it very quickly. For us, it was learning the lesson of not just going for that one, record cell, but understanding what the manufacturable technology limits are and having a process window that’s big enough to actually work with.”

Matt Reese, an NREL senior scientist and CdTe lead, recalled when, several years ago, the NREL group wanted to identify the sources of voltage loss in CdTe cells compared with competing technologies. The group developed experimental models and determined the problem was coming from the copper used to dope the CdTe cells. “Copper moves around a lot and is one of the biggest causes of instability and limits the efficiency,” Reese said.

First Solar found out NREL was working on this, and told NREL they would like the research to be conducted as precompetitive, meaning it would be done much more openly and for the purpose of developing new commercially applicable technologies.

“It turned out we were able — for the first time and using single crystals — instead of getting 0.85 volts, we were able to get out more than a volt,” Reese said. “We understood what was wrong with the system. Once we had this demonstration, First Solar was very excited and started working on its copper replacement process.”

Nature Energy published a paper on crossing the 1-volt barrier with single crystals. Three years later, NREL and First Solar published a paper together, again in Nature Energy, showing that manufacturable thin-film CdTe devices doped with arsenic have efficiencies on par with copper (Cu)-doped devices and a much lower long-term degradation rate. This new technology, called “CuRe” (Cu Replacement), is currently being implemented in First Solar manufacturing lines, paving the way for CdTe cells to become even more efficient and reliable.

Brandi Williams (left) and Brian Loskorn work in the Edge Trim Station on the Series 4 production line at the First Solar manufacturing plant in Perrysburg, Ohio. Photo by Dennis Schroeder, NREL.

Through the years, as technology has advanced, First Solar has occasionally licensed NREL-developed technology, the earliest on record coming in 2007. Reese said having First Solar succeed is a win and it means they are doing something right. Kazmerski noted from the early days how those at NREL also felt any success from industry reflected well on them.

NREL and First Solar continue to work together closely. “NREL recently designed and built a successful vapor transport deposition tool like the one used by First Solar to deposit CdTe films,” said David Albin, another lead CdTe researcher at NREL. “This increases the relevancy of NREL’s work for First Solar. In addition to a long-standing Cooperative Research and Development Agreement (CRADA), we have recently partnered with them in two different cost-share projects that are studying the compatibility of NREL intellectual property with their process.”

Gang Xiong, director of the First Solar California Technology Center, has witnessed the NREL–First Solar collaboration on CdTe research for a decade. “The collaboration is fruitful as we can leverage the complimentary strength of both parties to advance the CdTe solar cell technology together,” he said.

How NREL and First Solar Helped Shape the Solar Industry

The significance of the partnership and the work jointly produced has had an impact on the solar industry beyond simply taking the last survivor of the initial wave of early CdTe companies to the top. It has established a blueprint for introducing and scaling up new technologies and helped push the boundaries and test the limits of what’s possible.

“We have a market of silicon that is always changing and improving and of course CdTe,” Kazmerski said. “If it wasn’t for CdTe, maybe we wouldn’t even be looking at perovskites now. People started to look for alternative thin films that are better. These guys are always keeping on top of things to see if they can’t themselves come into this and be a player or find out what the competition is doing. First Solar is here to stay with their CdTe, but they have shown that a thin film can be very, very competitive. The perovskite people are starting to mimic what First Solar did to show that these modules are really stable.”

Kroposki said First Solar got out in front of another emerging trend as well.

“Early on in the game, they decided to implement full-scale recycling, so they really understand the process end-to-end,” he said. “Only now are the crystalline manufacturers realizing they have to get into this recycling game and start to think about that.”

Barnes acknowledged the success of First Solar and called attention to the importance of having some healthy competition. She also said the fact that they are one of the few U.S. companies still in the business is also important, but First Solar has been looking to advance CdTe technology beyond just what it is using in its modules.

In March 2021, after a series of workshops begun in 2017, Colorado State University, the University of Toledo, NREL, and Tempe, Arizona-headquartered First Solar kicked off an alliance called the U.S. Manufacturing of Advanced Cadmium Telluride (US-MAC) photovoltaics consortium, designed “To further reinforce U.S. leadership in solar technology.”

The press release from the University of Toledo read, “US-MAC will work with its members to advance foundational science and engineering, stimulate innovation, and capitalize on shared resources and expertise. It aims to support increased production volume, optimize performance, and to diversify, integrate, and support the success of domestic firms.” US-MAC includes a total of 10 industry partners (including First Solar) interested in furthering the success of CdTe PV.

“This partnership is one of the best examples of why the lab was set up originally and why it was developed as it was,” Kazmerski said. “It showed that the lab could really help a U.S. industry.”

I don’t like paywalls. You don’t like paywalls. Who likes paywalls? Here at CleanTechnica, we implemented a limited paywall for a while, but it always felt wrong — and it was always tough to decide what we should put behind there. In theory, your most exclusive and best content goes behind a paywall. But then fewer people read it! We just don’t like paywalls, and so we’ve decided to ditch ours.Unfortunately, the media business is still a tough, cut-throat business with tiny margins. It’s a never-ending Olympic challenge to stay above water or even perhaps — gasp — grow. So.

If you like what we do and want to support us, please chip in a bit monthly to help our team do what we do! Thank you! Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

Have a tip for CleanTechnica, want to advertise, or want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Cadmium telluride solar cells

Home / Energy Power / Cadmium Telluride Photovoltaic Market

Cadmium Telluride Photovoltaic Market Size, Share Industry Analysis, By Application (Residential, Industrial Commercial, Utilities) And Regional Forecast 2023-2030

Cadmium telluride photovoltaics is also called Cadmium telluride solar cell or cadmium telluride thin film, a photovoltaic device that produces electricity from sunlight by using a thin film of cadmium telluride. Cadmium Telluride photovoltaic are less efficient than crystalline silicon devices but are cheaper to produce and technology has the potential to surpass silicon in terms of cost per kilowatt of installed capacity. The rising adoption of cadmium telluride in the electro-optic modulator, owing to the high electro-optic coefficient is another factor expected to further support the growth of the market during the forecast period.

Based on the application, the global cadmium telluride photovoltaic market can be segmented into residential, industrial commercial, and utilities. The utility segment held a dominant share of the market expected to grow at the highest CAGR during the forecast period. Several ongoing utility-scale solar projects are in pipeline across the globe. Recently in May 2020, Amazon Announces Five New Utility-Scale Solar Projects to Power Global Operations in China, Australia, and the U.S.

The residential segment is expected to contribute significantly during the forecast period. The increasing number of residential construction projects and growing public awareness regarding the usage of renewable and efficient energy sources are estimated to drive the residential segment during the forecast period.

Growing awareness among the consumers coupled with rising government investment in renewable energy, especially solar energy is a major factor expected to drive the growth of the global cadmium telluride photovoltaic market. over, the introduction of Feed-in Tariff (FIT) by developing countries such as China and India is resulting in increasing demand for cadmium telluride in solar cells which is another factor expected to boost the growth of the global market over the forecast period. However, stringent government regulations related to the harmfulness of cadmium and lower productivity of cadmium telluride solar cells are some of the major factors restraining the growth of the global market

Key Players Covered:

Some of the major companies in the global cadmium telluride photovoltaic market are First Solar, Advanced Solar Power, Antec Solar, Calyxo, CNBM Optoelectronic Materials, CTF Solar, D2solar, Dmsolar, RSI, UPT Solar, and Willard Kelsey (WK) Solar, among others.

The global cadmium telluride photovoltaic market is studied across different regions like North America, Europe, Asia Pacific, Latin America, and Middle East Africa. Europe dominated the cadmium telluride photovoltaic market owing to the rising government FOCUS toward the adoption of sustainable energy. Due to the implementation of stringent emission norms in European countries, the dependence on renewable sources is rising for the production of electricity. Additionally, the emerging research activities in the field of thin-film solar cells are projected to open up new avenues for the cadmium telluride photovoltaic market growth in the upcoming years. North American is another major region for the cadmium telluride photovoltaic market. The U.S. dominating the North America cadmium telluride photovoltaic market owing to the growing demand for photovoltaic installation in the residential commercial sectors.

The market in the Asia Pacific region expected to grow at a significant pace during the forecast period, owing to increasing government initiatives towards using renewable energy sources, increasing construction activities, and rising adoption of solar PV. China, India, and Southeast Asia countries are a lucrative region for the market.

Segmentation

By Application

By Geography

- North America (U.S. and Canada)

- Europe (UK, Germany, France, Spain, Italy and Rest of Europe)

- Asia Pacific (Japan, China, India, Southeast Asia, and Rest of Asia Pacific)

- Latin America (Brazil, Mexico, and Rest of Latin America)

- Middle East Africa (South Africa, GCC and Rest of Middle East Africa)

Cadmium Telluride Solar Cell (CDTE) Market Scope and Segmentation

Report Metric

2020 (Customizable to 2014. 2019)

Revenue in USD Billion, Volumes in Units, Pricing in USD

Source (Tellurium, Cadmium), Application (Solar PV, Optical Lenses and Windows, Electro-Optic Modulator, Nuclear Spectroscopy, Infrared Optical Material), End User (Residential, Commercial, Industrial and Utility)

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America

Greatcell (Australia), Exeger Operations AB (Sweden), Fujikura Europe Ltd. (U.K.), G24 Power Ltd. (U.K.), Konica Minolta Sensing Europe B.V. (Netherlands), Merck KGaA (Germany), Oxford PV (U.K.), Peccell Technologies, Inc. (Japan), Sharp Corporation (Japan), Solaronix SA (Switzerland), Sony Corporation (Japan), Ricoh (Japan), First Solar. (US), SunPower Corporation (U.S.), Suniva Inc (U.S.), Tata Power Solar Systems Ltd. (India), SHARP CORPORATION (Japan), ALPS Technology Inc. (U.S.), Solaris Technology Industry, Inc. (India), GREEN BRILLIANCE RENEWABLE ENERGY LLP (India), Trina Solar (China), Canadian Solar. (Canada),

Market Definition

Cadmium telluride solar cells (CDTE) are based on the thin film layer of cadmium telluride (CDTE) which is used as semiconductor to convert absorbed sunlight into electricity. In cadmium telluride solar cells (CDTE), the lower electrode is formed by layer of copper-doped carbon paste whereas the upper layer is formed by cadmium-based stannous oxide (Cd2SnO4) or tin oxide (SnO2).

Cadmium Telluride Solar Cell (CDTE) Market Dynamics

The increase in awareness among the market players and buyers regarding the adverse effect of other solar cell on environmental increase the demand of cadmium telluride solar cell (CDTE) because it is renewable source-based power. Also, the rise in the dependence on unconventional energy sources has a positive impact on the market, which are expected to drive the market’s growth.

The high absorption property of cadmium telluride solar cell (CDTE) are expected to drive the demand of the cadmium telluride solar cell (CDTE) in the market. Cadmium telluride is a direct-bandgap material with bandgap energy from 1.4 to 1.5 (eV), it is nearly optimal for changing sunlight energy into electricity using a single junction.

The rise in the number of installation of solar system further influence the growth of the cadmium telluride solar cell (CDTE) market. The rise in demand of cadmium telluride solar cell (CDTE) due to rising need to decline the of solar cells modules are expected to drives the growth of the market.

over, change in lifestyle, surge in investments, Rapid urbanization and augmented consumer spending positively impact the cadmium telluride solar cell (CDTE) market.

The recent technical advancements reducing the production cost of the cadmium telluride solar cell (CDTE) which extend the profitable opportunities to the major market players in forthcoming period. Furthermore, improvement in infrastructure development activities will further expand the growth of the cadmium telluride solar cell (CDTE) market.

over, increasing the number of strategic collaborations and emerging new markets will act as market drivers and increase the beneficial opportunities for the market’s growth rate.

Restraints/ Challenges

However, Due to the negative impact of cadmium on the environment, the government has imposed some stringent regulations which are expected to obstruct the demand of the cadmium telluride solar cell (CDTE) in the market.

The lower productivity of the cadmium telluride solar cell (CDTE) compared to other alternatives might be hinder the growth of the cadmium telluride solar panel market globally during the forecast period of 2022-2029.

This cadmium telluride solar cell (CDTE) market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue s, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the cadmium telluride solar cell (CDTE) market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

COVID-19 Impact on Cadmium Telluride Solar Cell (CDTE) Market

The COVID-19 negatively impacted the cadmium telluride solar cell (CDTE) market due to the strict social distancing and lockdowns to contain the corona virus. The partial shutdown of the business, economic uncertainty and low consumer confidence have impacted the demand for cadmium telluride solar cell (CDTE) technology. The supply chain was hindered during this pandemic along with delayed logistics activities. However, the cadmium telluride solar cell (CDTE) market is anticipated to recover its pace during the post pandemic scenario.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

New solar consortium says it will push CdTe thin-film efficiency to 30%

Various university, research and commercial solar companies involved with cadmium telluride (CdTe) thin-film solar panel manufacturing have formed the U.S. Manufacturing of Advanced Cadmium Telluride (US-MAC) photovoltaics consortium.

Led by the Wright Center for Photovoltaics at The University of Toledo, Colorado State University (CSU) and the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL), the group will advance foundational science and engineering, stimulate innovation and capitalize on shared resources and expertise. It aims to support increased CdTe solar production volume, optimize performance, and to diversify, integrate and support the success of domestic firms.

CdTe solar modules currently meet approximately 40% of the domestic utility-scale PV market demand — all coming from First Solar, the world’s largest CdTe solar panel manufacturer, with its home factory just outside Toledo, Ohio.

“While already enjoying great success in the marketplace, recent scientific developments make it clear that CdTe PV has significantly more potential for dramatically higher module efficiency, lower cost, increased lifetime energy, and more Rapid production. This is all achievable with the concerted cooperation and investment that will be pursued by US-MAC,” said NREL Laboratory Director Martin Keller.

CdTe solar modules already exhibit a 19% commercial module efficiency. US-MAC will push the efficiency closer to the maximum theoretical efficiency of approximately 30%, develop advanced tandem and bifacial concepts for even higher performance, and extend the already excellent lifetime. CdTe annual production can be increased at least by a factor of 10 through focused and coordinated research and development.

US-MAC currently consists of an executive board that includes CSU, NREL and the University of Toledo, and has 10 industry members that comprise its industrial advisory board: 5N Plus, Consolidated Research Systems, Direct Solar, First Solar, Lucintech, Nious Technologies, Pilkington North America, Sivananthan Laboratories, Toledo Solar, and Uriel Solar Energy.

“The membership believes that CdTe is only at the beginning of its technology maturation curve, with much work still to do,” said Dr. Michael Heben, director of the Wright Center for Photovoltaics at UToledo, professor of physics and McMaster endowed chair. “The Secretary of Energy’s recent announcement of a new CdTe Accelerator Program reinforces this belief.”

Efforts to establish US-MAC began more than a year ago and a Memorandum of Understanding was fully executed on March 11, 2021. First Solar was selected by the industrial advisory board to be its representative to the executive board for a first three-year term. The executive board will work with the industrial advisory board and other key points of contact in other organizations to advance the goals of US-MAC.

The organizers and members of US-MAC intend for the consortium to be inclusive as it pursues the mission to strengthen American leadership in manufacturing of CdTe PV. Discussions are underway with Arizona State University, the University of Delaware and the University of Utah, as well as with other companies, to join an expanding US-MAC network.